Abstract

Much progress has been made with the OPEnSampler! The frame is lightweight, the entire system fits into the Pelican rolling cooler, and the sample control works as expected. 24 bags fit with room inside the frame, and the system can be set on any face without issues, easing maintenance, testing, transport, and drawing out samples. Some issues persist in this iteration, namely light leaking from the bags and a low flow rate due to the cheap pumps.

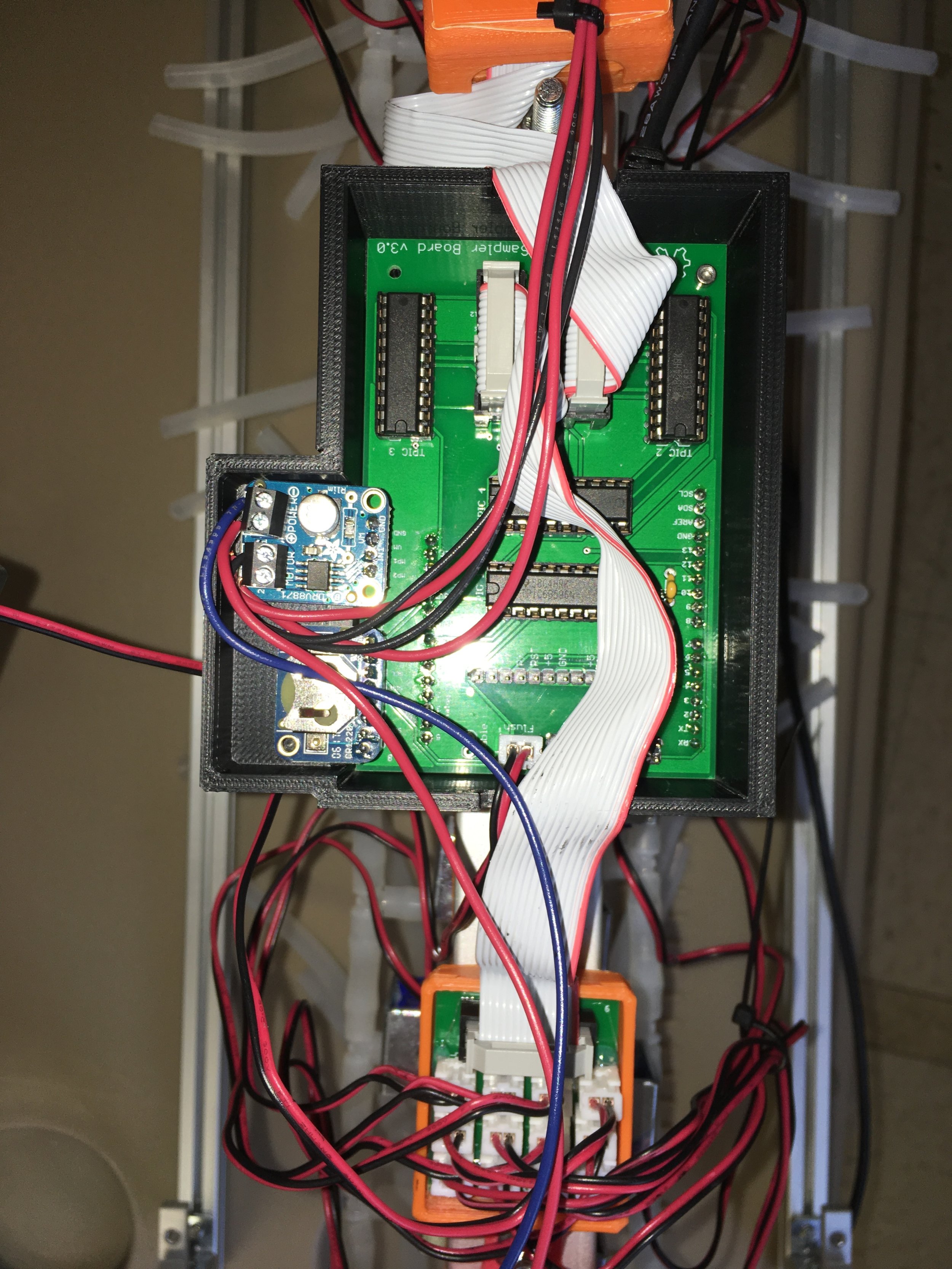

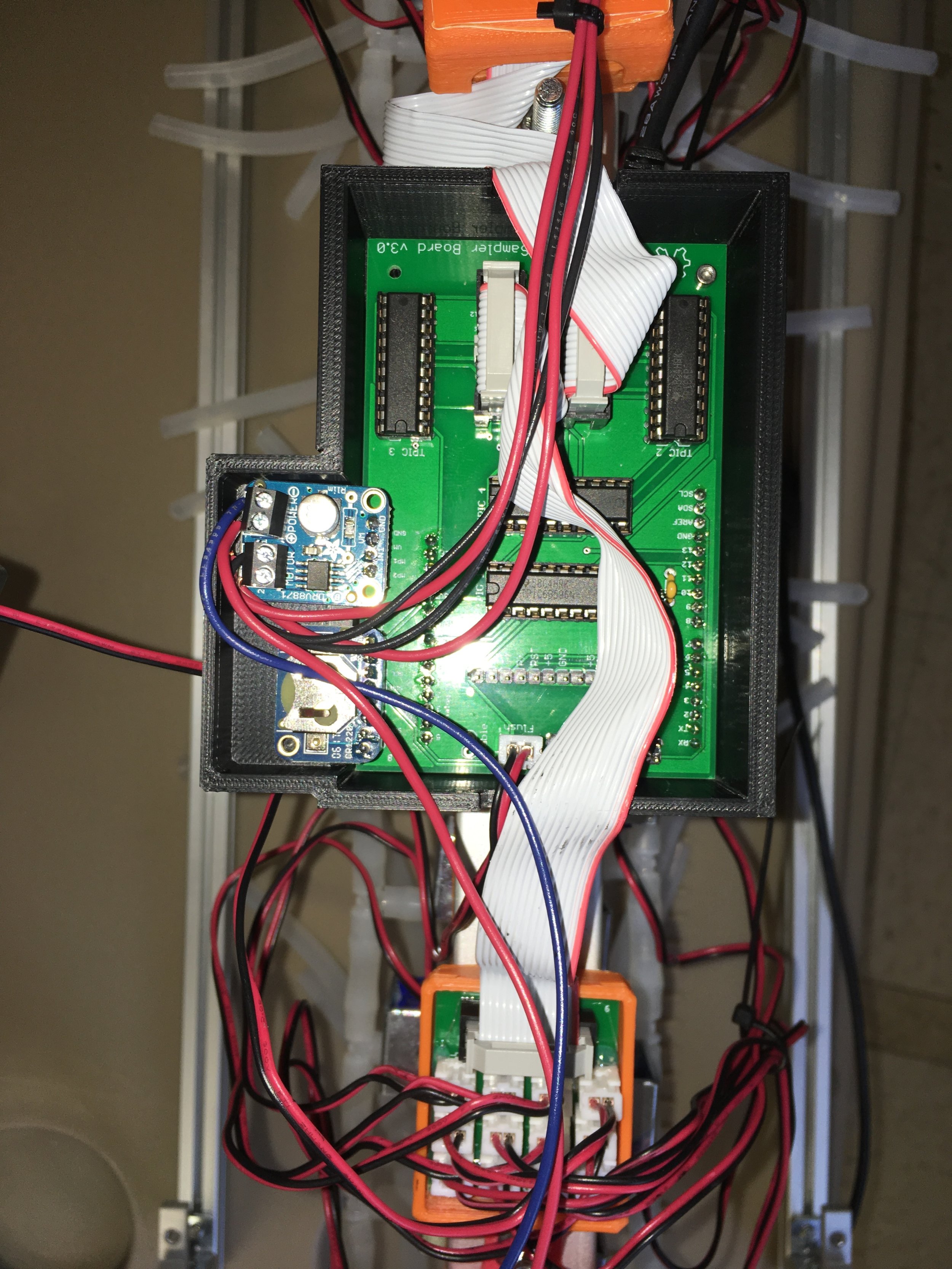

Electronics

The electronics of the sampler have evolved. They consist of an Arduino Uno connected to three custom PCBs: two Valve Breakout Boards (VBBs) and one Main Control Board (MCB). The MCB connects directly to the Arduino and includes the shift registers to control the valves, the motor breakout board for the pumps, the real time clock, and receptacles for ribbon cables connecting to the VBBs. The VBBs break out the open-drain outputs on the shift registers to 12 JST terminals each, corresponding to one valve each. Doing this reduced the wire-spaghetti caused by directly soldering wires to each valve.

Frame:

Slotted aluminum extrusion can be ordered at specific lengths with a tight tolerance for several dollars per piece, allowing the frame to be assembled in minutes with purchased corner brackets. A lighter but sufficiently strong 15mm aluminum extrusion was used, reducing the weight of the frame to just over 2 kg. The design of the frame allows the OPEnSampler to be tilted in any direction without issue.

Hydraulics:

Water to be sampled is pulled through an open end of 3/16” ID silicone tubing via two $12 peristaltic dosing pumps in parallel. The pumps claim to have a head height of “10m” and a flow rate of up to 150 ml/min, but in practice the numbers are about half those values. Further testing will be carried out, but the pumps will be replaced with a $60 peristaltic pump from a more reputable company supposedly capable of a 350ml flow rate.

Down-line of the pumps water fills the rest of the tubing, leaving the exit end if the flush valve is opened, or is pushed into a sample bag when its respective valve is opened. To draw sampled water out of a bag, its respective valve is opened and the pumps are powered in reverse using the H-bridge motor breakout board bought from Adafruit.

Current Bugs

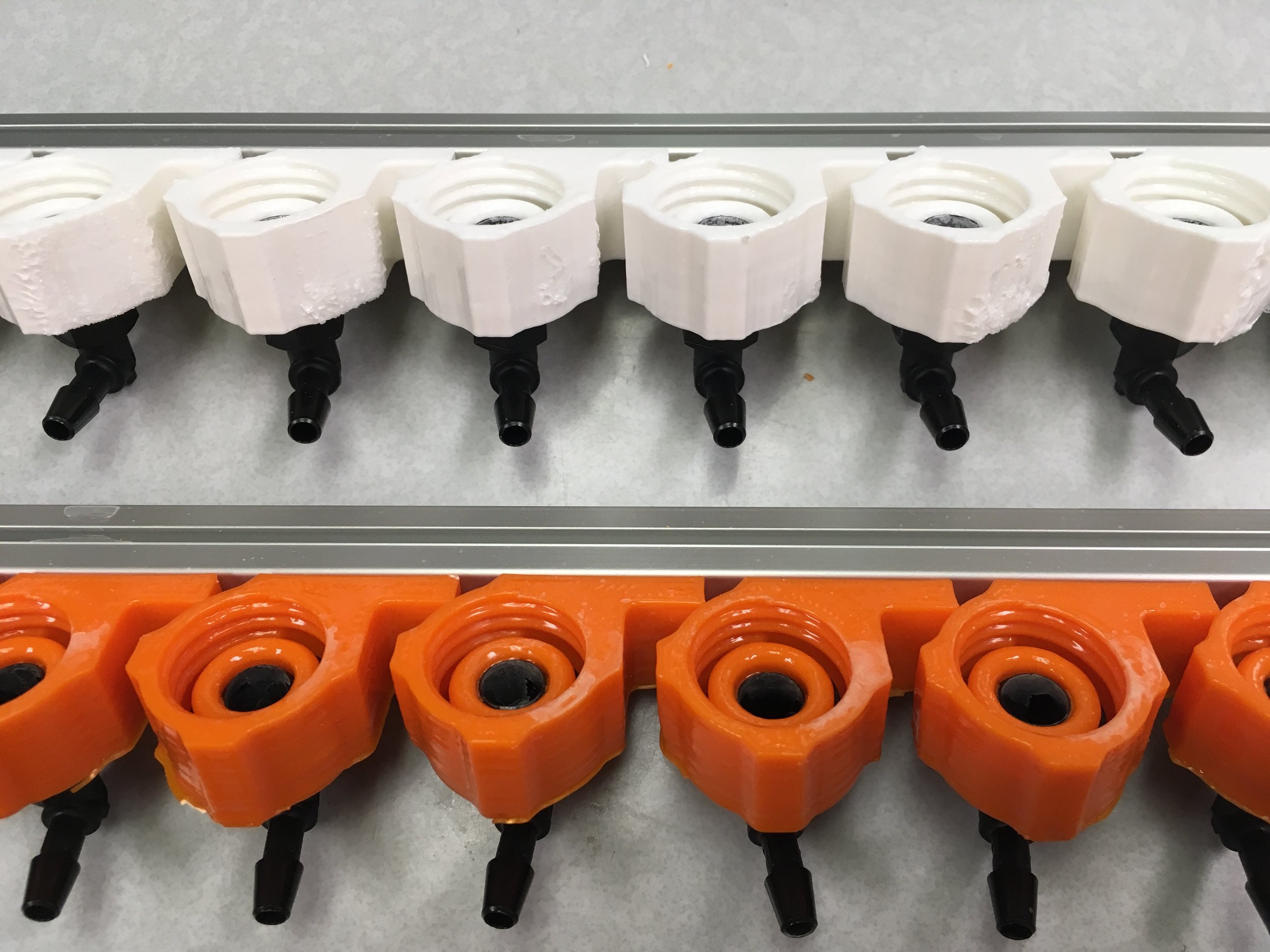

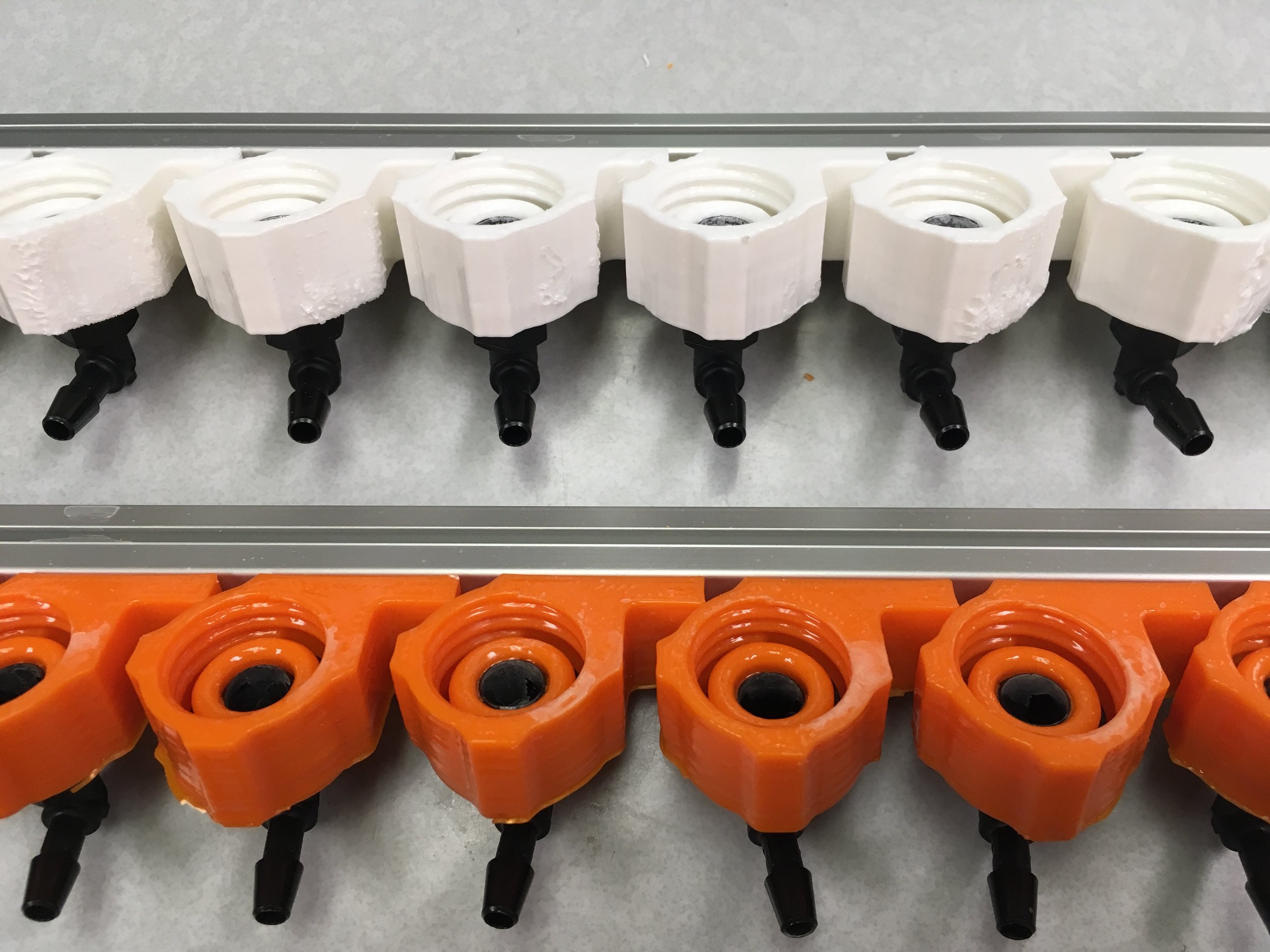

There are a couple known bugs in the system and one major design flaw that limits the functionality of the device. The first bug is mechanical: the bags leak when they are upside down. Initially, this was a very significant amount, draining the bags overnight. Teflon tape was wrapped around the elbow connectors that screw into the printed bag caps, and the leaking was reduced to a few mL per hour. Initial tests of new bag caps with changed O-Ring gland dimensions, a 3% smaller diameter through-hole for the elbow fittings, and the replacement of teflon tape with a gorilla-glue and acetone coat show very promising results with no leaking in the first two caps tested. 24 new caps were printed, processed, and are currently drying before testing tomorrow morning.

The second bug is intermittent and will be difficult to fix. On occasion, valve 7 becomes permanently powered and will stay open regardless of what serial commands are fed to the Arduino. This is characterized by a lack of actuating sound when the command “V7 1” (valve 7 on) is sent, by bag 7 filling despite sending the commands to fill another bag, and by an actuating sound upon powering on the device. This bug is not consistent and the cause is currently unknown. Battery power was suspected initially, but when probed the battery read a high 12.7 volts.

The major design flaw is the low flowrate of the pumps, including the new pump selected. The EPA recommends a line velocity of greater than 2 ft/s when sampling for suspended solids such as sediments (link). With 3/16” ID tubing, this equates to a flow rate above 600 mL/min. Low flow pumps were chosen because high-flow peristaltic pumps cost between several hundred and several thousand dollars. A 3D printed pump head with a store-bought DC gear-motor is being investigated, though a <$100, 1000ml/min 12V pump has been found on AliExpress and will be tested out before a DIY pump is developed.

Conclusion

While a significant portion of this writeup was dedicated to discussing the current issues with the device, the OPEnSampler is working almost exactly as expected. If a solution to the leaking problem is not found soon, the bags can simply be reoriented to sit upright for this current version. The pumps will be sufficient in sampling for analytes that aren’t large-particle suspended sediments.