Abstract:

We observed our $1 solenoid valves were failing under low pressure conditions. After some investigation and testing, we found we could safely orient the valves in to ensure the flush valve will fail first while the sample valves will form quite strong seals when closed. This solution allows us to continue to use the cheaper valves and keep our cost of materials down.

Introduction:

Cost is a limiting factor when choosing components for the OPEnSampler. There are many repeat components, including the 24 sample containers, 52 compression fittings, 25 feet of tubing, 32 aluminum brackets, 16-20 pieces of aluminum extrusion, and 26 solenoid valves. Increasing the cost of any of these by several dollars would increase the total cost of materials by $100 to $200, depending on the component. We chose cheap $1 solenoid valves from AliExpress with this factor in mind, knowing the next best alternative were adafruit’s $7 solenoid valves. It turns out, however, that our $1 solenoid valves are quite weak and fail under normal use conditions due to the water pressure from the pump. Luckily, the solution was quite simple.

Explanation:

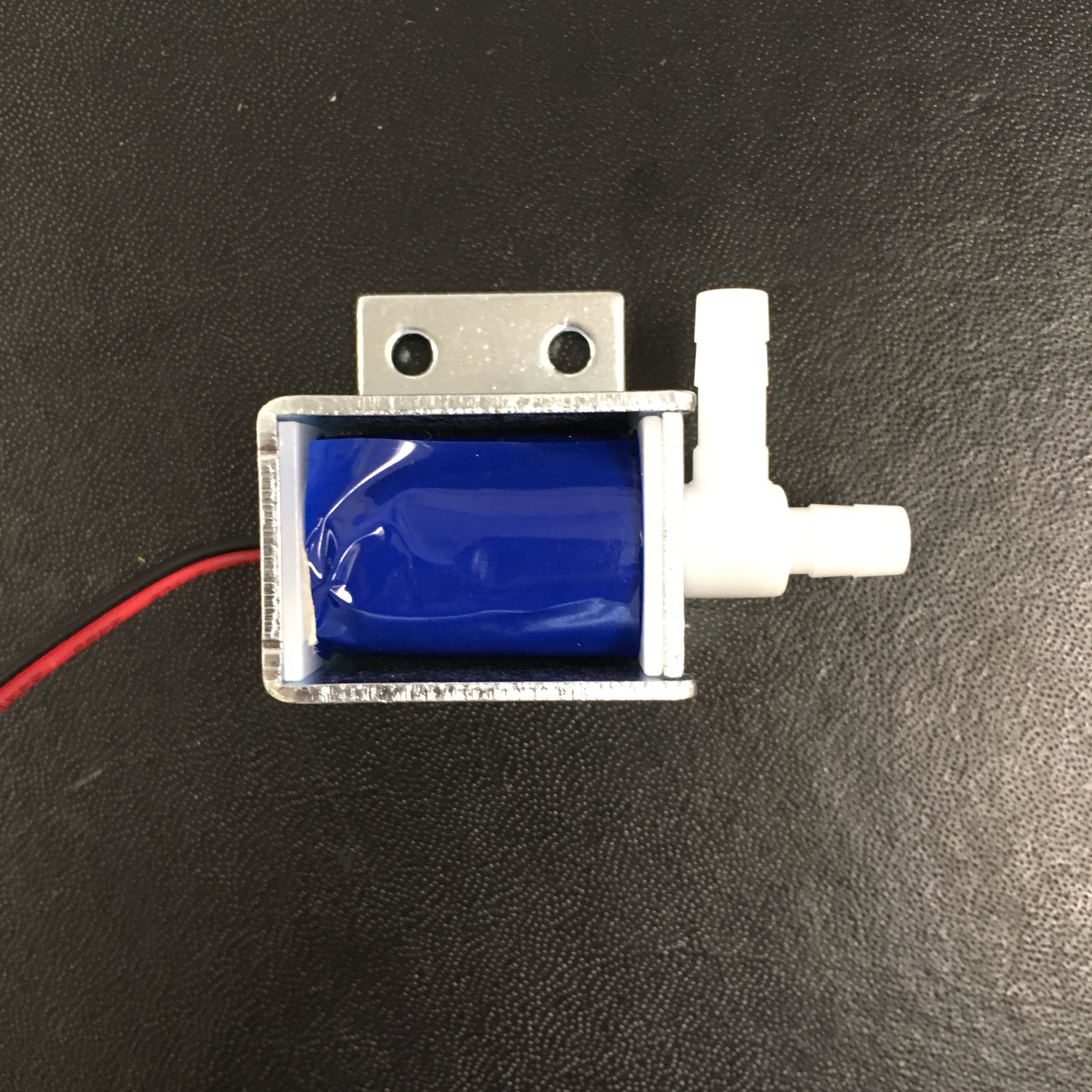

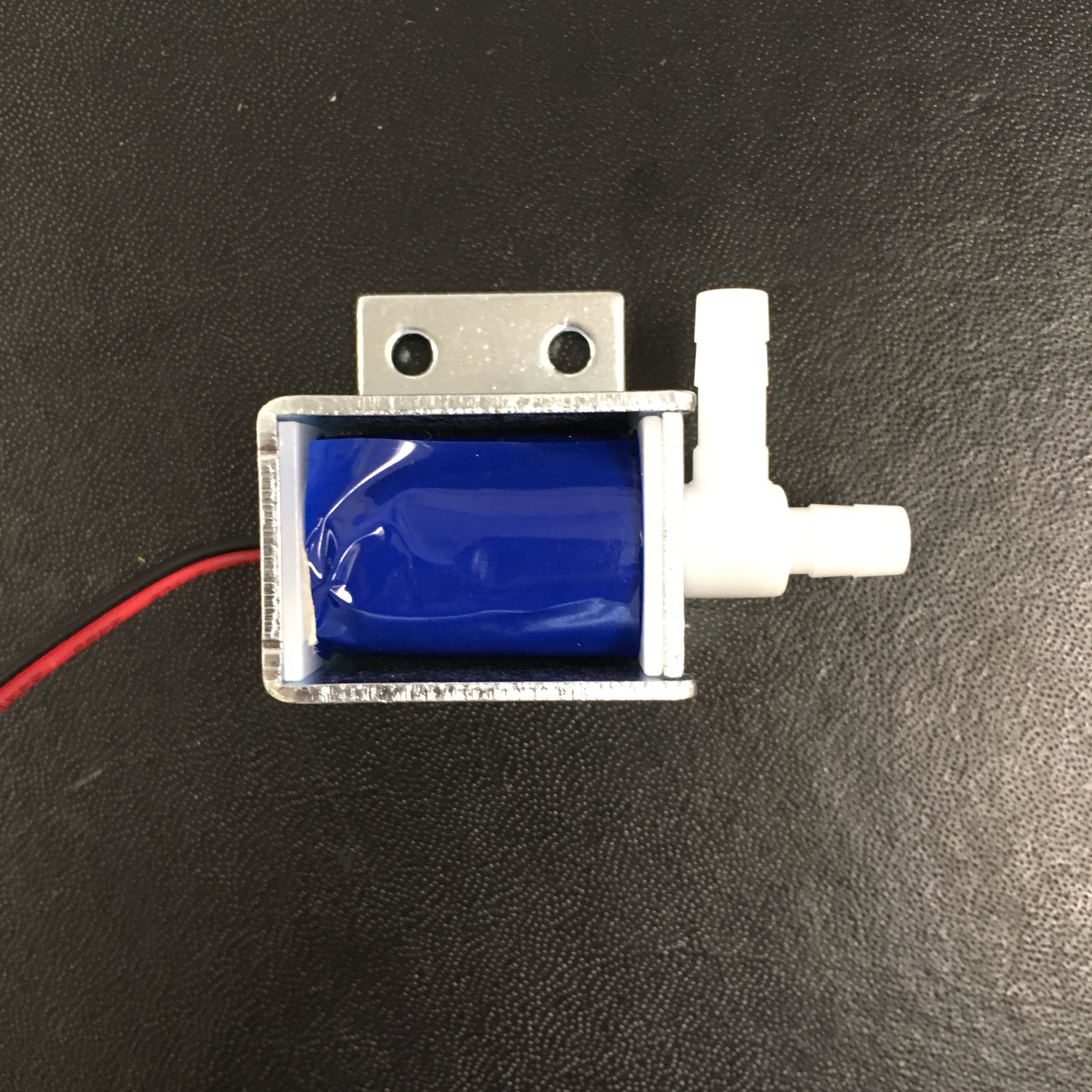

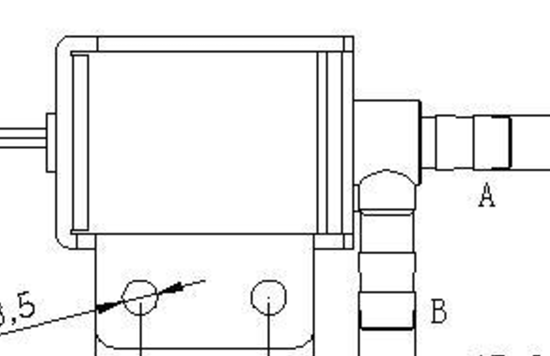

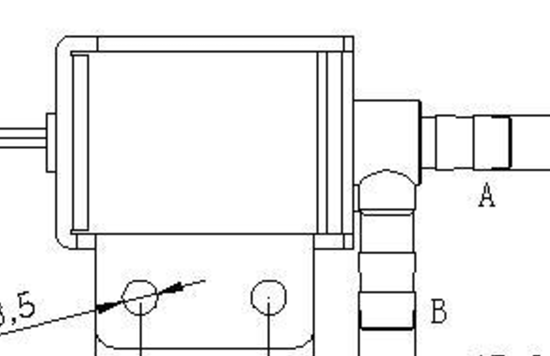

Solenoid valves open and close the flow of water with a linear actuator that pushes out or pulls in. In cheap normally-closed solenoids a spring holds the actuator out, pressing an o-ring against the face of the inlet as a seal. When current passes through the solenoid, the actuator pulls in against the spring and water is allowed to pass from inlet to outlet. The diagram below, taken from dyxminipumps.com, shows how our $1 valve’s inlet and outlet (openings A and B, respectively) are perpendicular to each other.

Using A as the inlet and B as the outlet, the valve will fail under quite low pressures. This is because the actuator is only blocking flow because of the force of the small spring; a small pressure from a pump only has to surpass the force of the spring to force the actuator backwards, opening flow from A to B. Orienting flow in the reverse direction, however, yields different results. Any pressure applied from opening B acts perpendicular to the motion of the actuator, neither adding nor subtracting from its closing force. In this orientation the valve will stay closed under very high pressures and a pressure buildup will cause other components of the water line failing first, such as the tubing popping out of fittings. This is quite undesirable in the normal application of these valves, such as in coffee machines, but we can take advantage of the failure behavior of the two orientations for the OPEnSampler.

By directing flow in the sample valves from B to A they will stay closed in the event of a pressure buildup, maintaining the integrity of the samples by preventing cross contamination. If the flush valve is oriented opposite, from A to B, it will be the weakest point in the water line and will fail first, effectively becoming a pressure relief valve for the system so that the water is released out the drain before fittings break.

This was tested in the lab by connecting the outlet of the pump directly to each of the valve’s openings in turn and running until failure. The pump ran for two minutes without valve failure while B was connected as the inlet and A the outlet, but failed after a few seconds in the A-B orientation.

Conclusion:

The sample valves will be oriented with flow from B to A and the flush valve will be oriented A to B. By taking advantage of the failure conditions of each orientation we can continue to use the cheap $1 valves without worrying about their low-pressure rating. This not only reduces further design work and prototyping but also saves about $150 per unit compared to the $7/piece alternative.