Major Research in Sustainable Food Processing and Packaging

- Reduce Food Loss and Waste Using Innovative Food Coating Techniques

- Develop Eco-Friendly Food Packaging to Reduce Impact to Environment and Provide Convenience to Consumers

- Upcycle Food-Processing Byproducts for Novel Food and Packaging Applications

- Investigate Emerging Food Processing Technologies

Reduce Food Loss and Waste Using Innovative Food Coating Techniques

We study functional edible coating techniques for:

- Reducing loss of fruit and wine grapes during production;

- Decreasing postharvest senescence and prolonging storability of fresh fruit and vegetables;

- Delaying quality deterioration and extending shelf-life of tree nuts;

- Retaining bioactive compounds, quality and nutrients of thermally and non-thermally processed fruit in aqueous media.

Postdoctoral Scholar, Dr. Taoran Wang, produces celluloses nanofibers from fruit pomace to create food coatings and films.

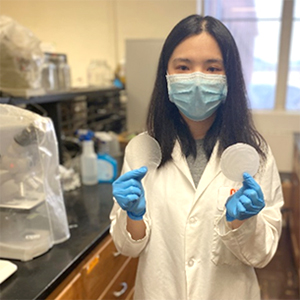

Graduate Research Assistant, Jerry Lin, studies edible coatings for retaining anthocyanins in thermal processed fruit.

Graduate Research Assistant, Trung Tran, develops edible coatings for preventing intake of wildfire smoke into fruit.

Develop Eco-Friendly Food Packaging to Reduce Impact to Environment and Provide Convenience to Consumers

We develop edible and biodegradable packaging with unique applications to replace single use plastic bags and wraps, such as edible, antioxidant, and heat sealable oil pouches; edible muffin liners and edible or biodegradable sheets for bakery goods; and edible and highly water resistant sheets and wraps.

Our aim is to not only reduce single use packaging, but also to extend product shelf-life and provide convenience to consumers. We also develop technology of creating compostable packaging containers using fiber-rich food processing byproduct.

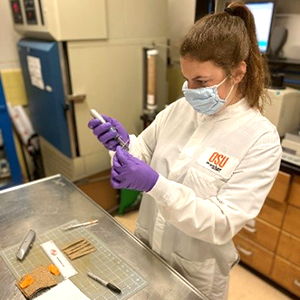

Graduate Research Assistant, Clara Lang, prepares compostable packaging using fruit pomace.

Graduate Research Assistant, Rachel Rosenbloom, creates edible and antioxidant edible oil pouches.

Graduate Research Assistant, Yi-Tin Shih, developes edible muffin liners.

Undergraduate Researcher, Andrew Choi, develops edible films using pomace extracts.

Upcycle Food-Processing Byproducts for Novel Food and Packaging Applications

We study value-added utilization of fiber-rich food processing byproducts (pomace, Brewer’s spent grains, hemp fibers, etc.) as functional food ingredients in a wide range of food products, extract cellulose for novel packaging applications, and as bulk materials to produce biodegradable and compostable packaging.

Pomace as antioxidant dietary fibers for food applications

Exact cellulose and other functional compounds from pomace to creating edible films

Pomace as bulk materials to create composite packaging products

Self-built, pilot-scale molded pulp machine to produce recyclable and/or compostable packaging using fiber-rich food processing byproducts

Investigate Emerging Food Processing Technologies

We study emerging food processing technologies for retaining quality and extending shelf-life of food and byproducts. We are especially interested in radio frequency (RF) dielectric heating and other energy efficiency drying techniques for saving energy and reducing greenhouse gas emission.

Postdoctoral Scholar, Dr. Chandrashekhar Sonar, dries hazelnuts using RF technology

Fruit pomaces are dried using high efficient impigement drying technique

Studies to retain quality and reduce shell cracking of dried hazelnuts