Author: Lars Larson

The devil is in the details, and the process of ensuring stable operation has been full of them.

Issues during recent deployment

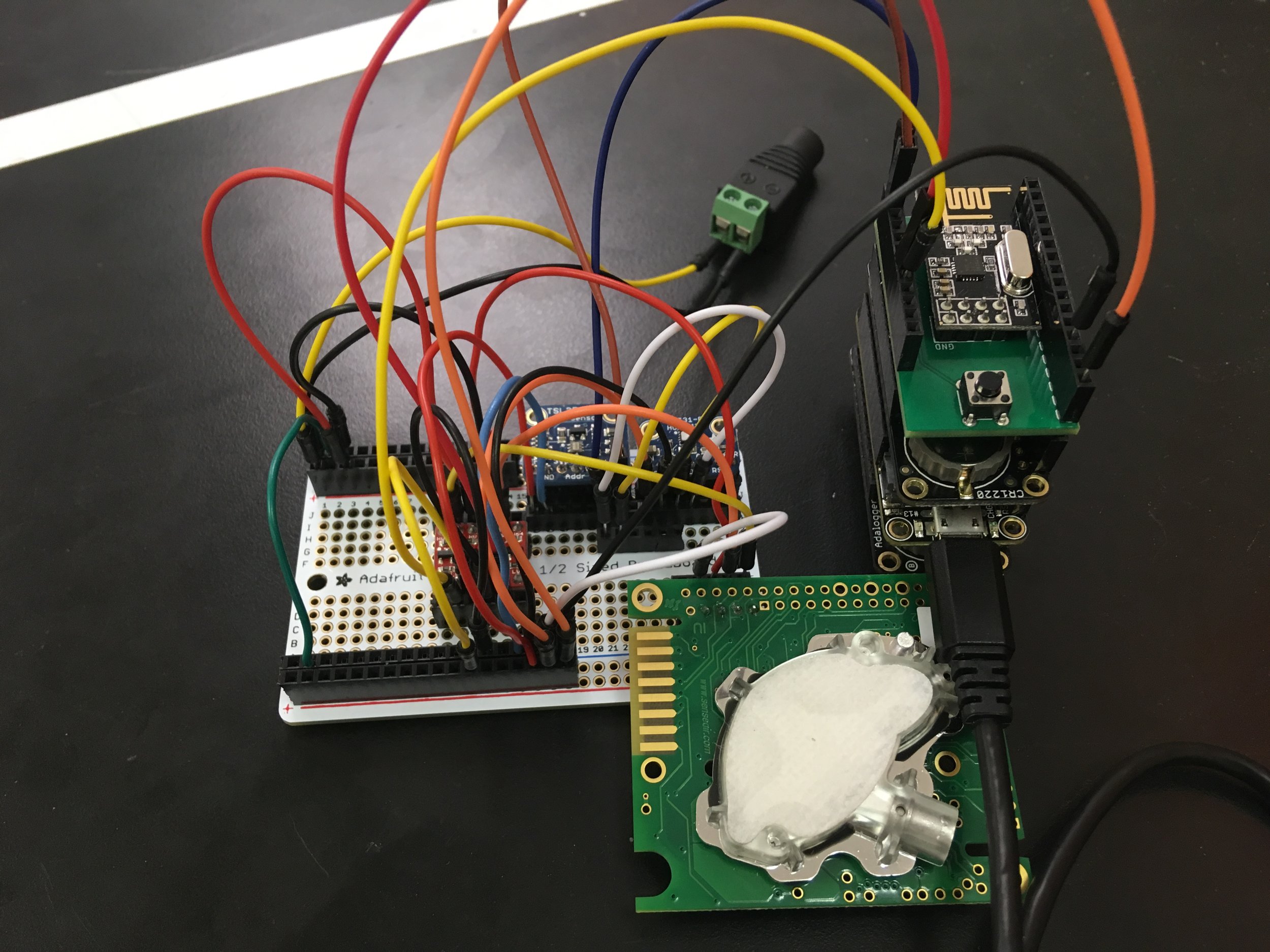

After multiple attempts with intermittent data transmission, it’s time to rebuild the nRF protocol. Some observations from the last deployment on 22 January 2019:

- Range tests (simple call-response between nodes) on site are robust beyond 400 meters, when the required range is only around 150 meters.

- Boosting the power with radio.setPALevel_MAX is essential to achieve desired range

- The entire sequence only works intermittently from HyperRail hub to the sensor package, back to the hub, and forwarded to the ethernet base station at the main office.

- The larger distance between the greenhouse and the ethernet hub is the component that is dropping data packets

Next Steps:

- The physical range constrained by the hardware does not appear to be the issue with the current nRF chips (Itead nRF24L01 + PA + LNA). Therefore, the code must be modified to address potential timing/network updating issues

- I will work with the Loom team this week to “Loomify” the nRF protocol by swapping in the Loom functions for each of the 3 nodes.

- Before next deployment, the system will be tested by recreating the field conditions to the best of our ability

On the bright side:

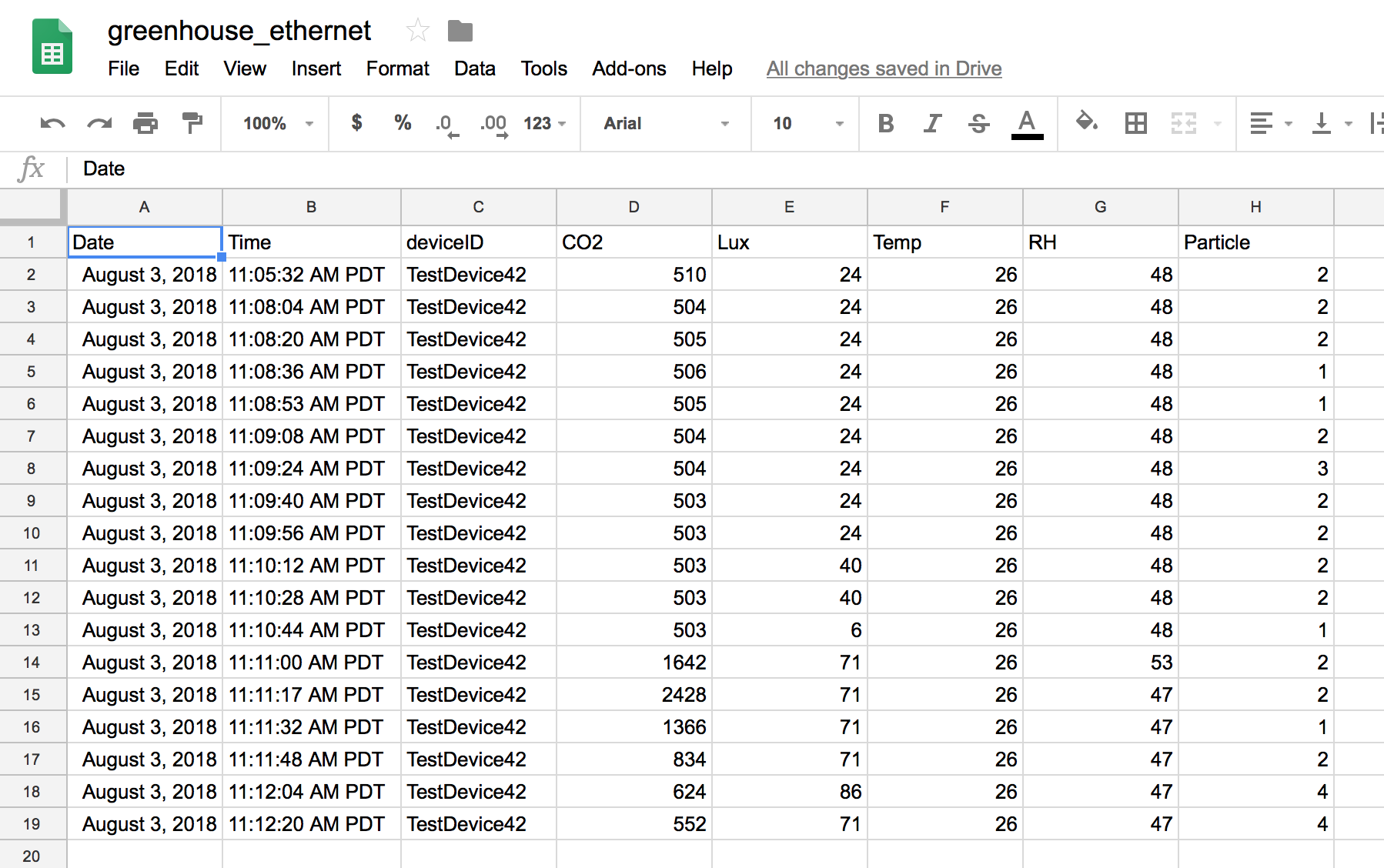

Around 50 data points were successfully sent, and the hardware was all very stable, especially the HyperRail system. The end is in sight!

Access eGreenhouse data stream live: