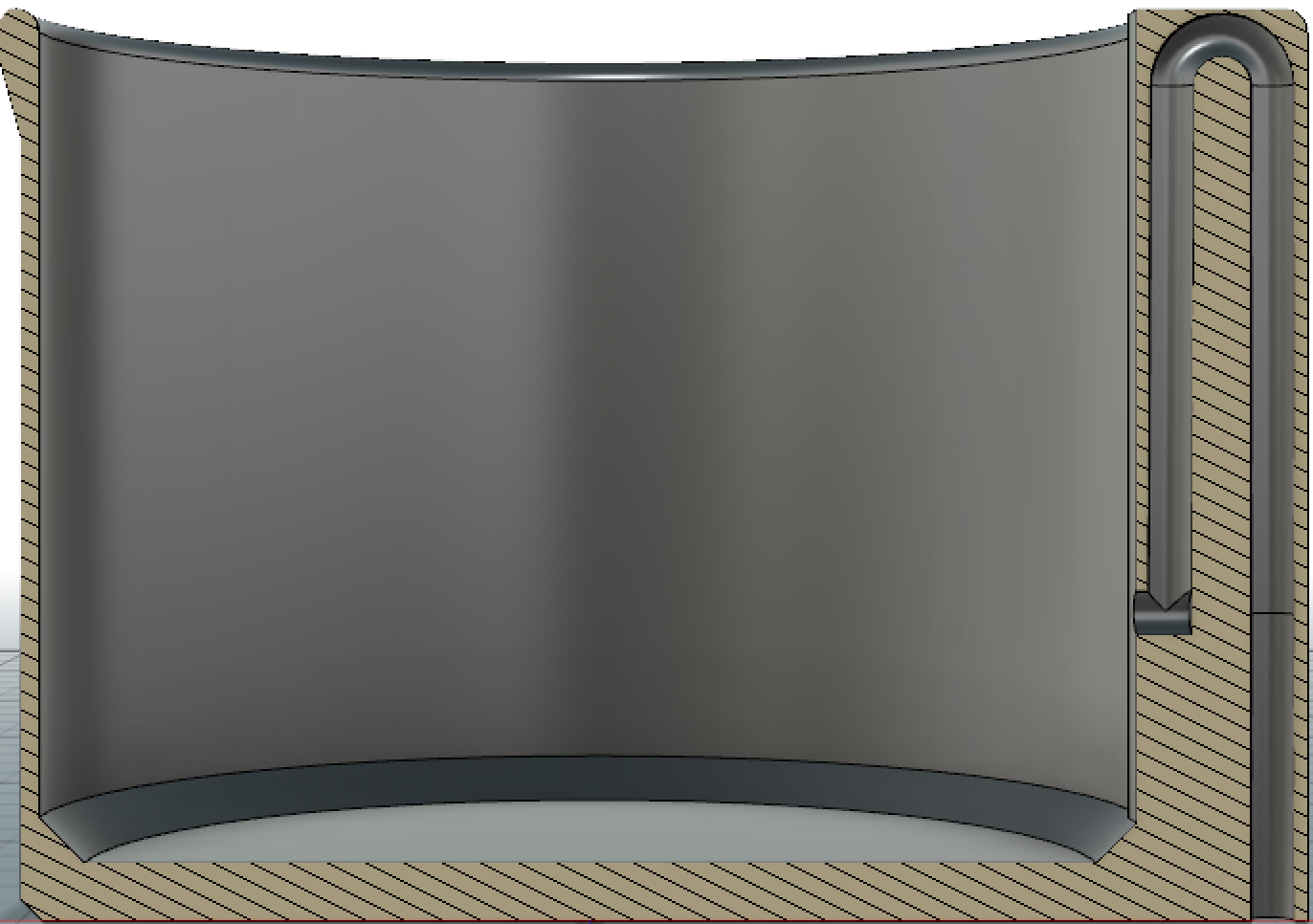

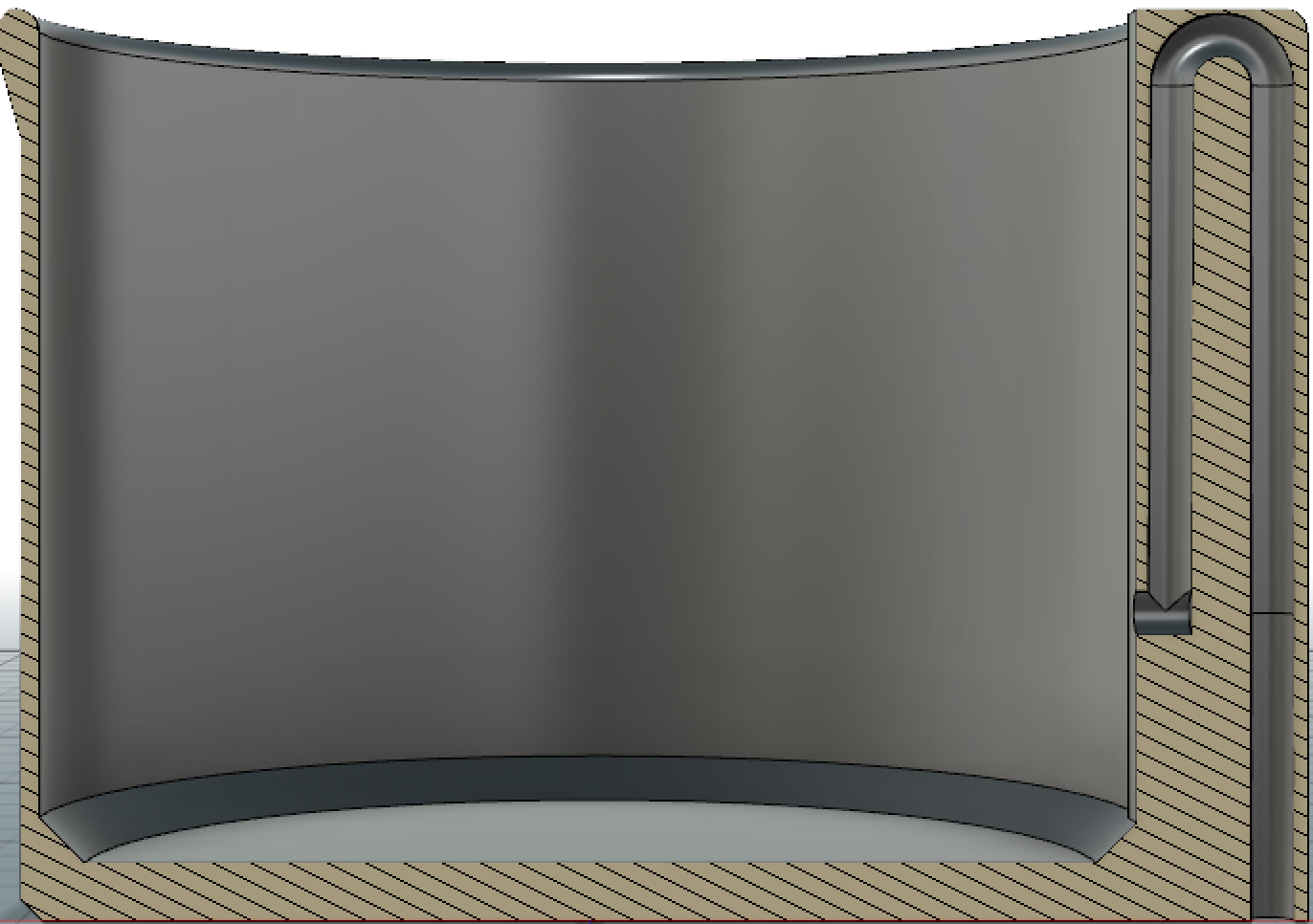

The rain validator needs to be drained after it reaches its maximum capacity. To do this we implemented the Pythagorean Cup principal. This allows for our validator to reach a certain liquid capacity and then drain. The principal is quite simple; the liquid is permitted to rise to a certain level and when the point is reached, a siphon will drain will the container.

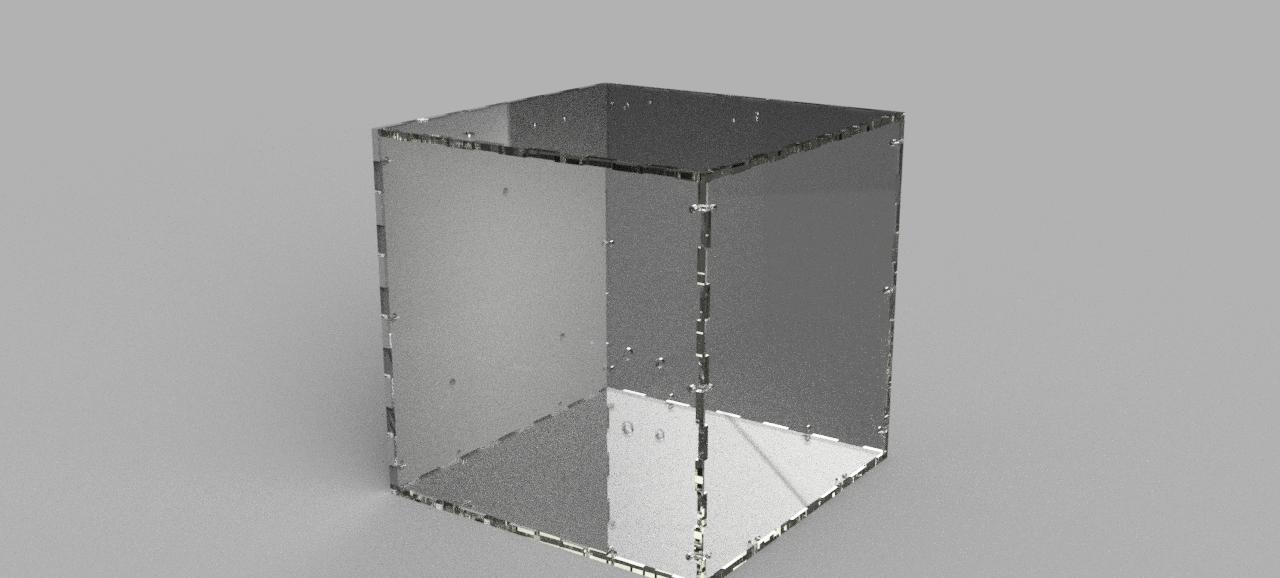

Rain Validator CAD rendering

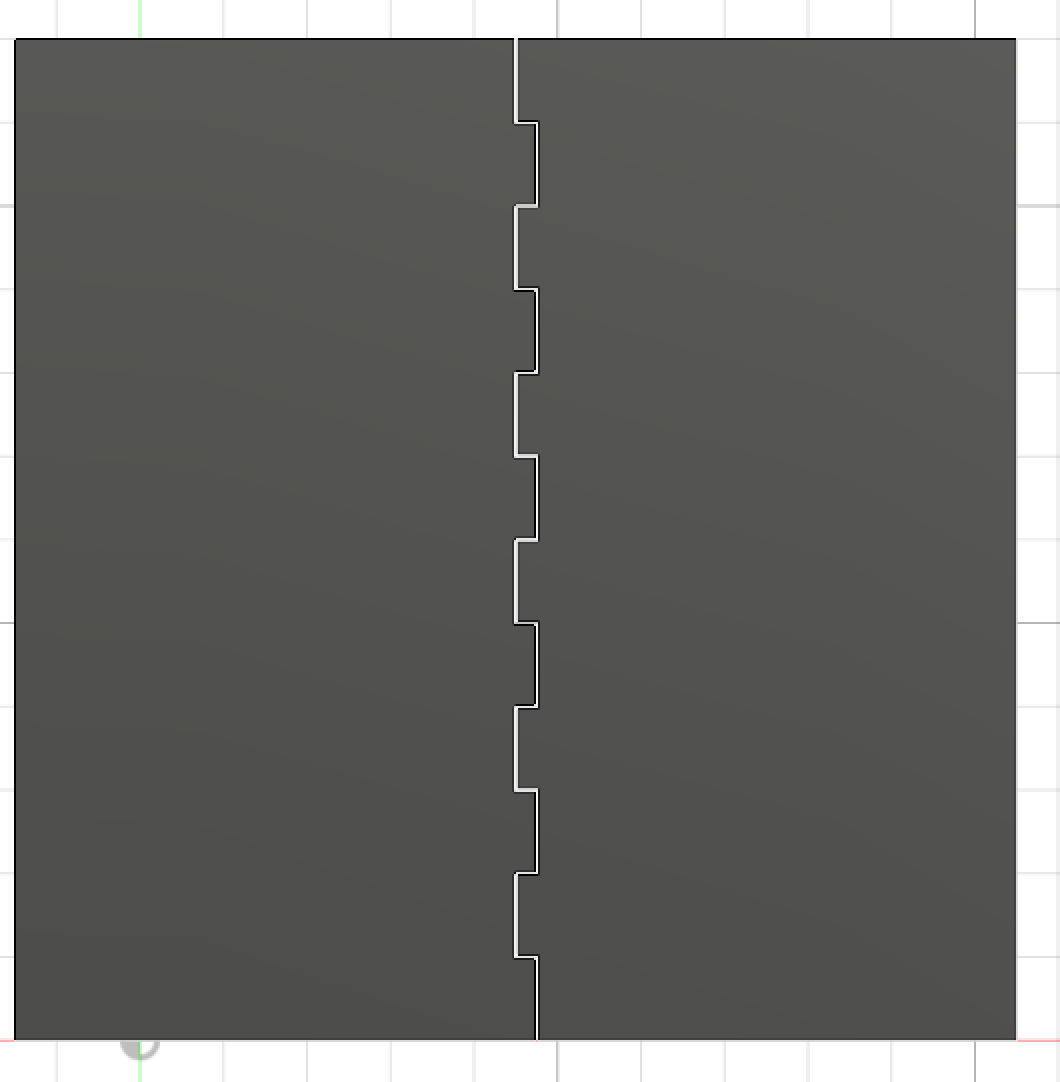

Section Analysis of the Rain Validator using Fusion360

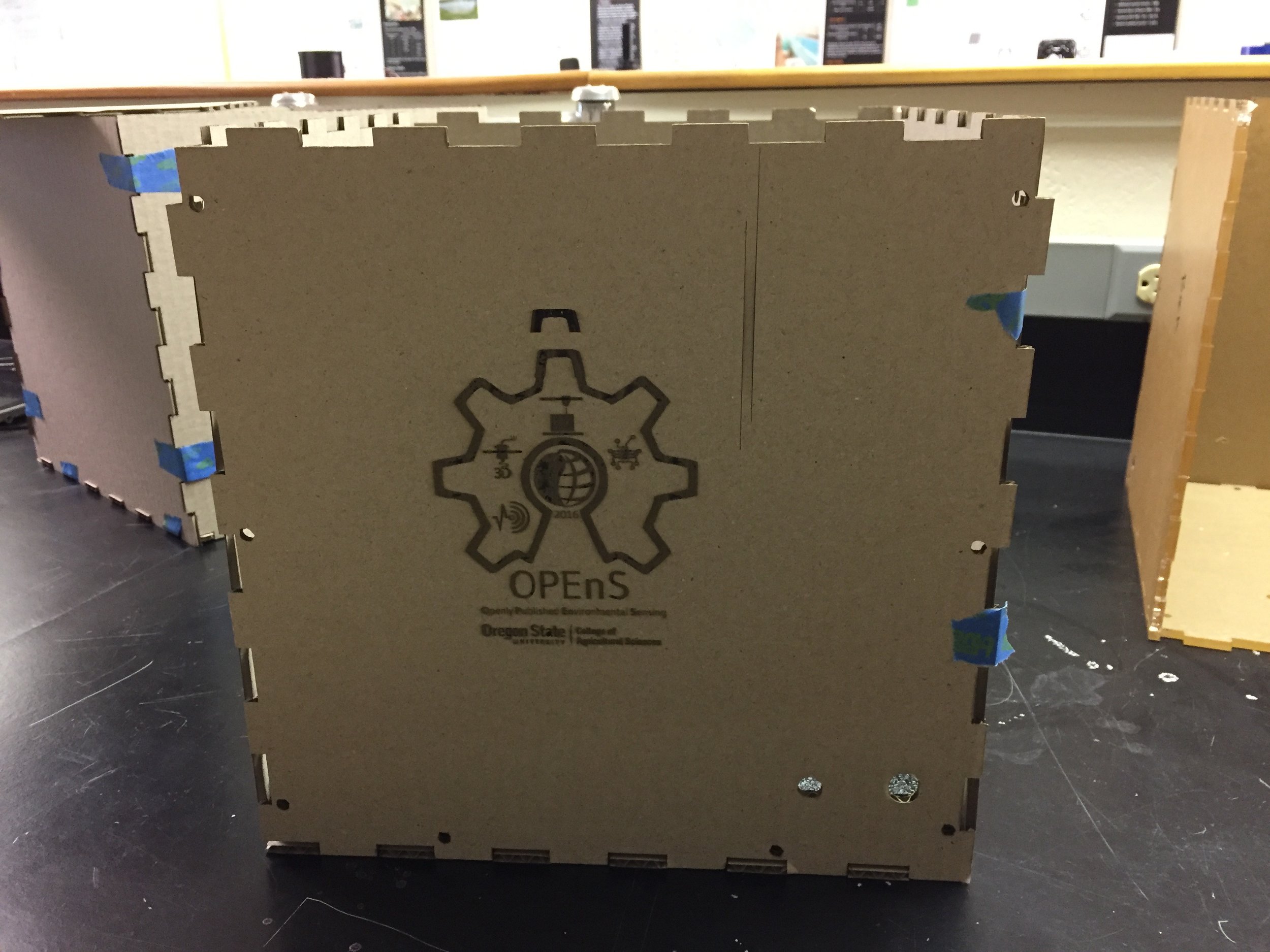

Our design works but needs modifications to be able to work appropriately. The following video is a demonstration of the current desing.