Abstract:

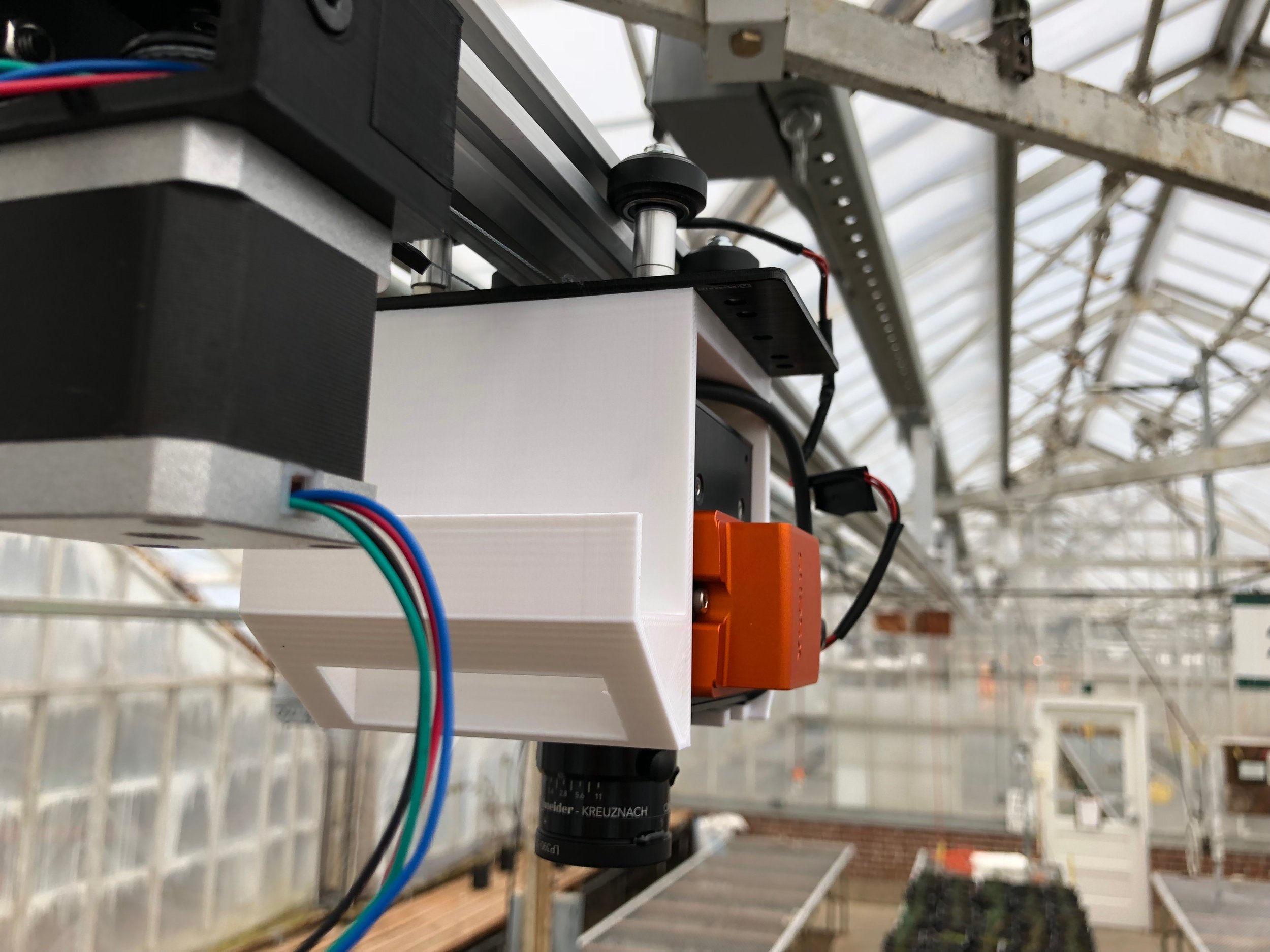

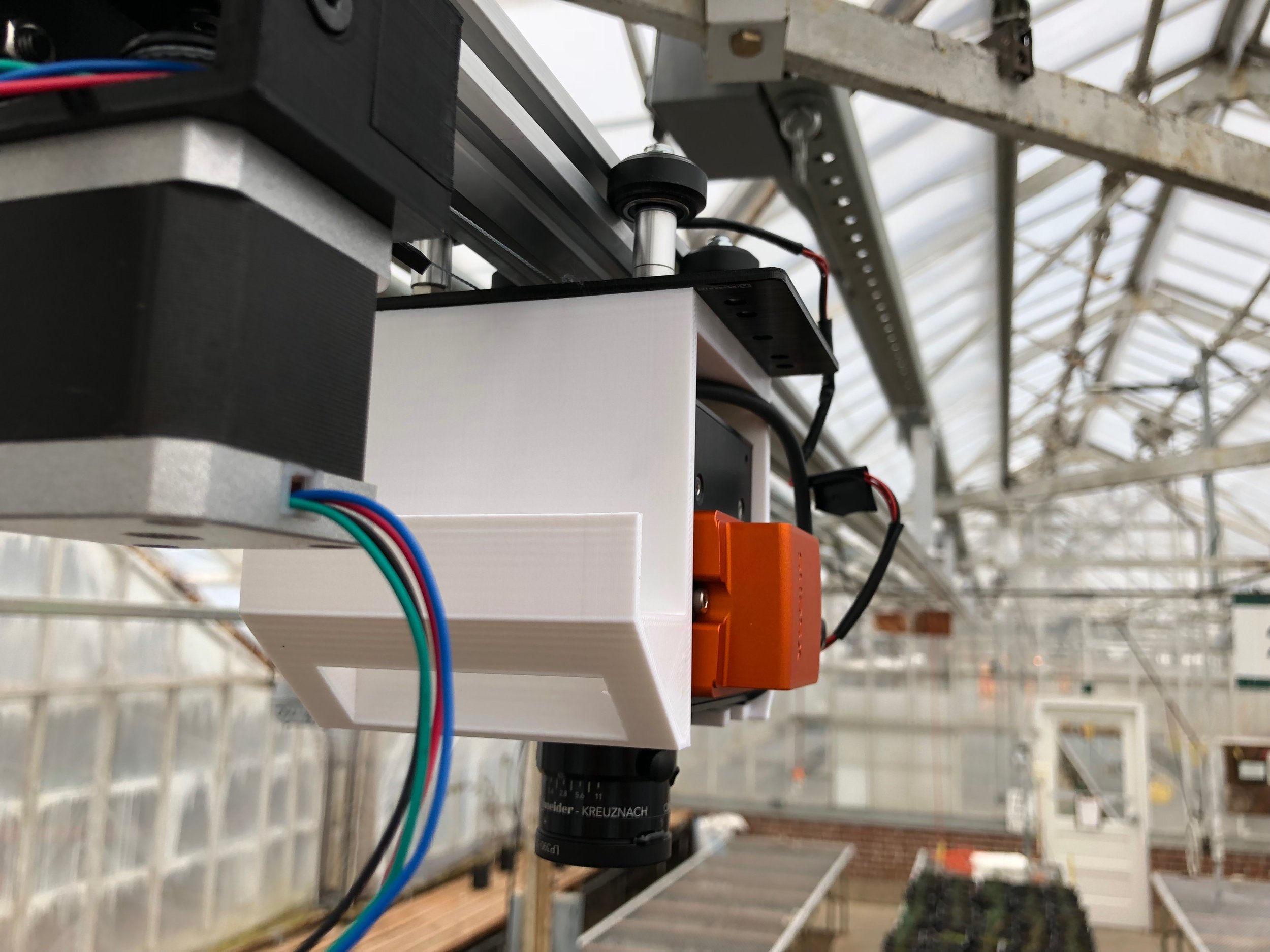

We took our first set of data of the pine seedlings using the HyperRail and hyperspectral camera. This post will be a summary of our setup for the data collection.

Objective:

Inform about our setup of the HyperRail and give an overview of the data collection.

Setup

We are using 9 meters of V-Slot (aluminum extrusion), a gantry set (rolling base), all the 3D printed parts located here, this attachment, an Arduino UNO, and the Big Easy Driver. The code is also located in the code section of the main page of this project.

Data collection Steps

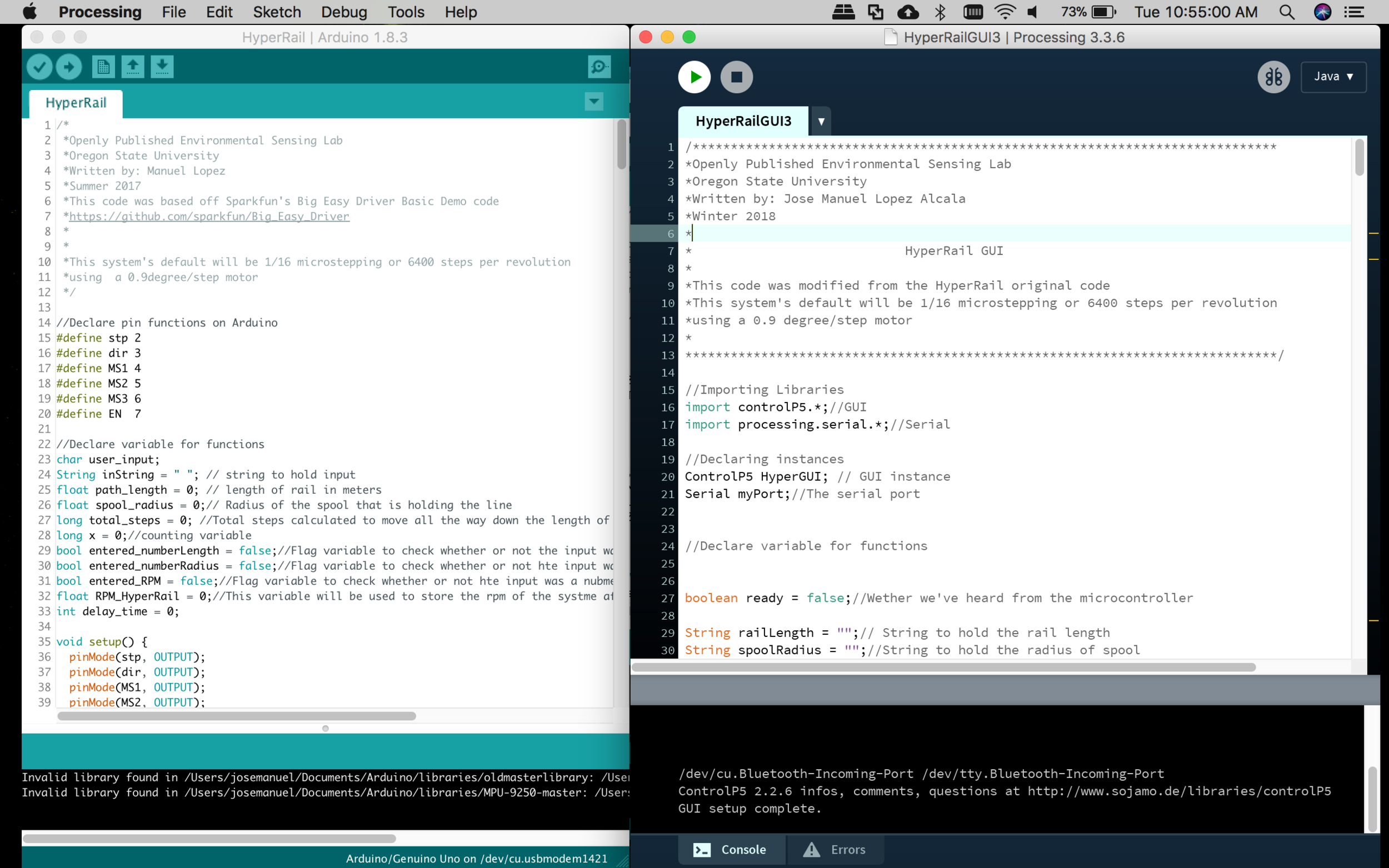

1. Upload the sketch to the Arduino Uno and connect the computer to the microcontroller

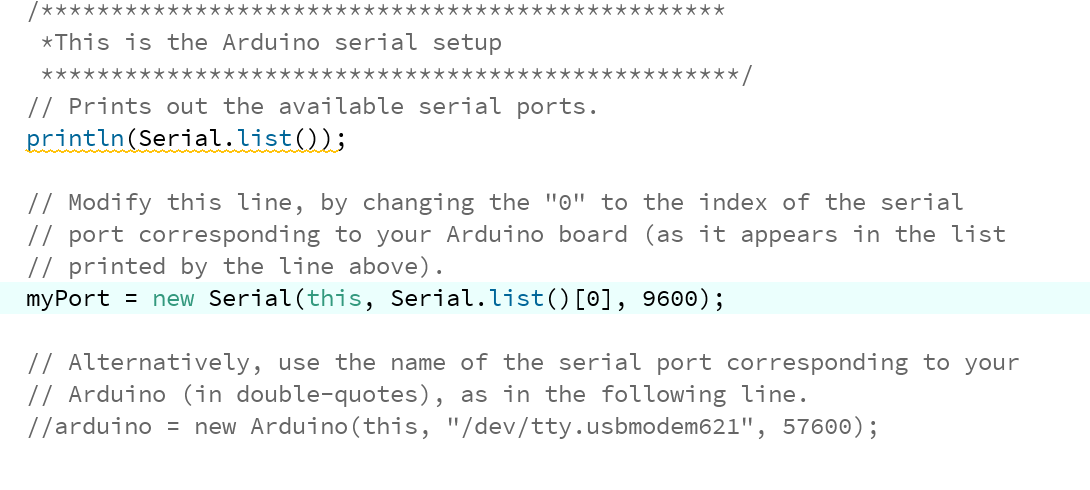

2. Run Processing sketch and wait for the list of ports to appear on the bottom of the IDE of processing. It will say something like, “/dev/tty…” or “com#”

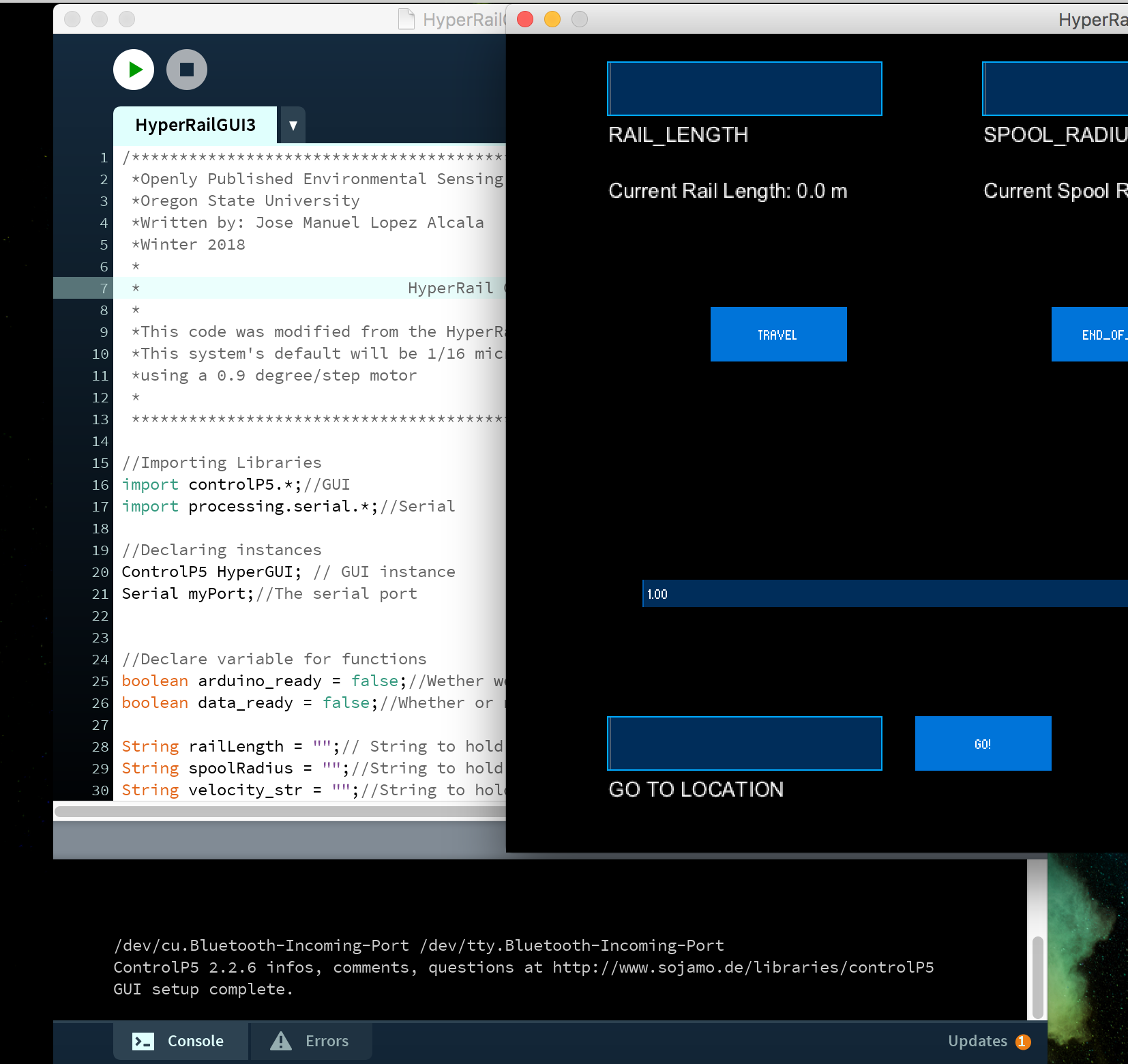

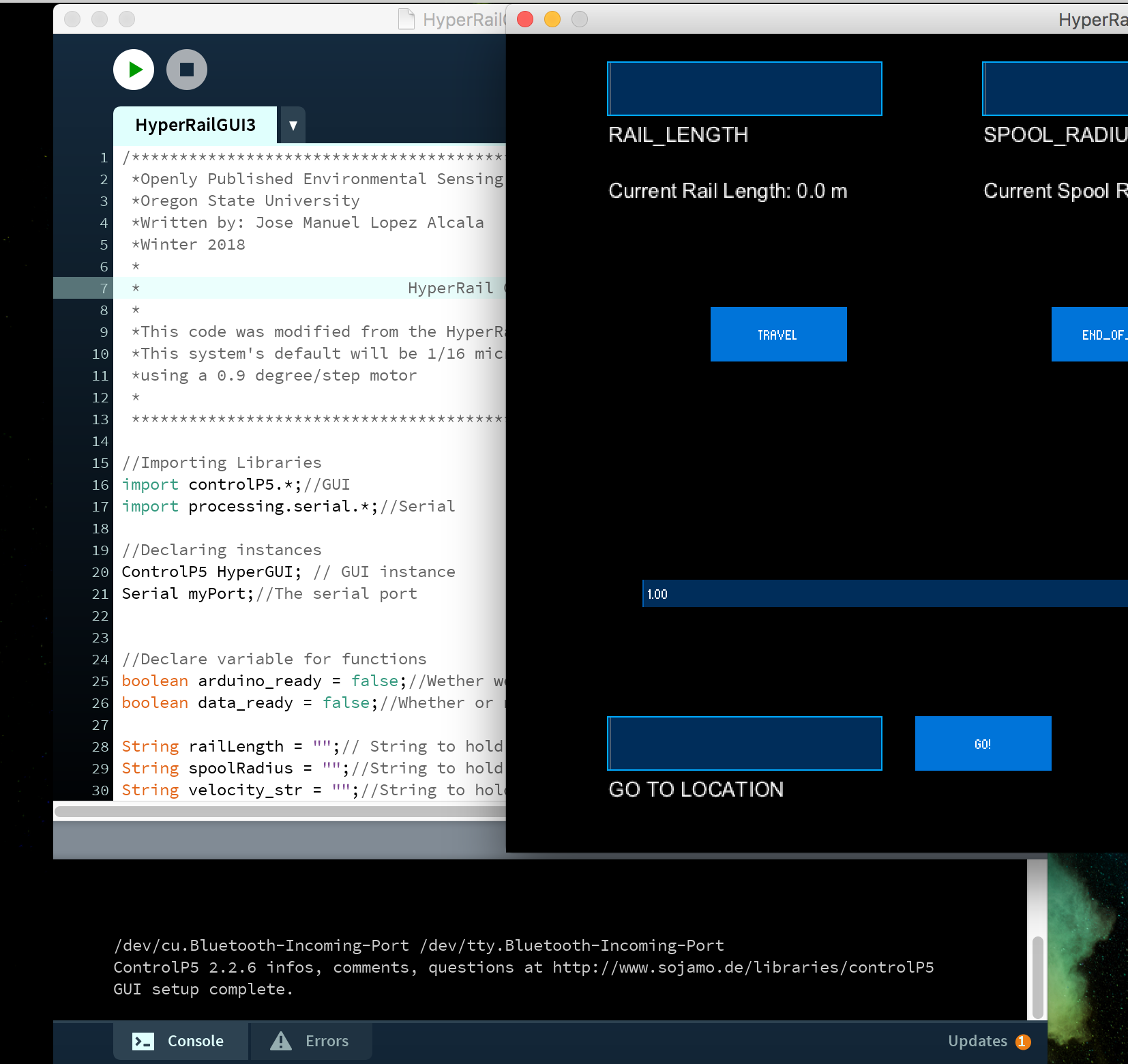

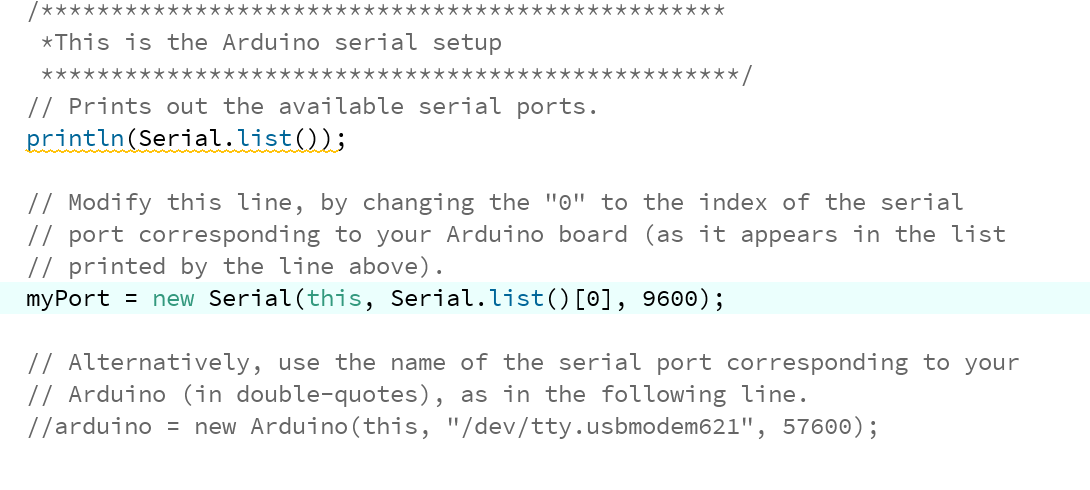

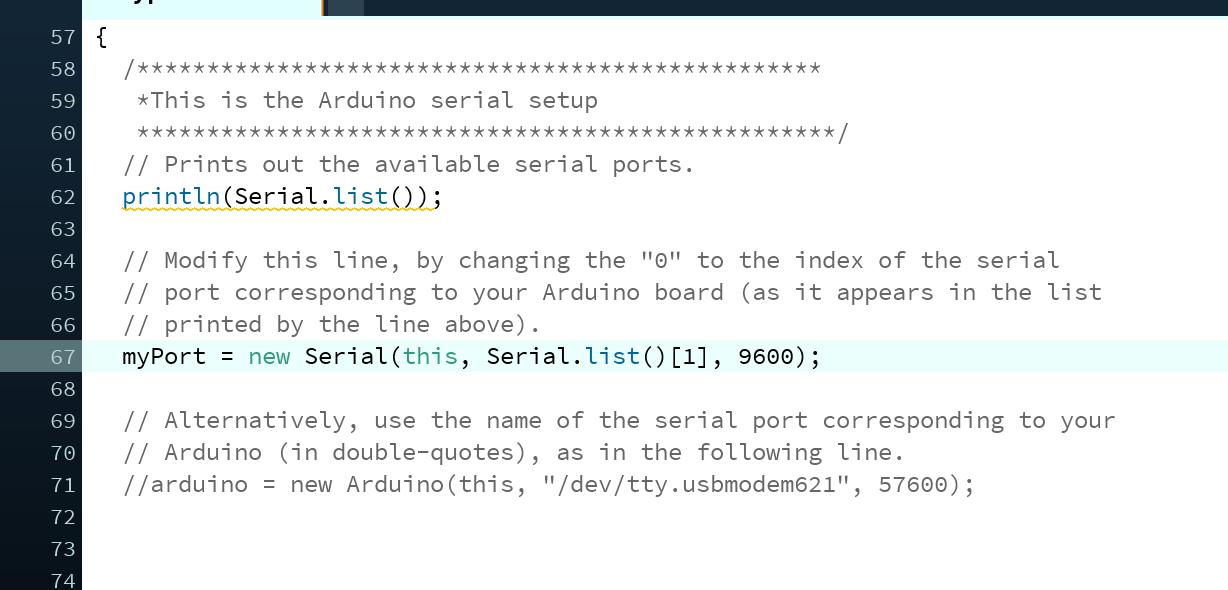

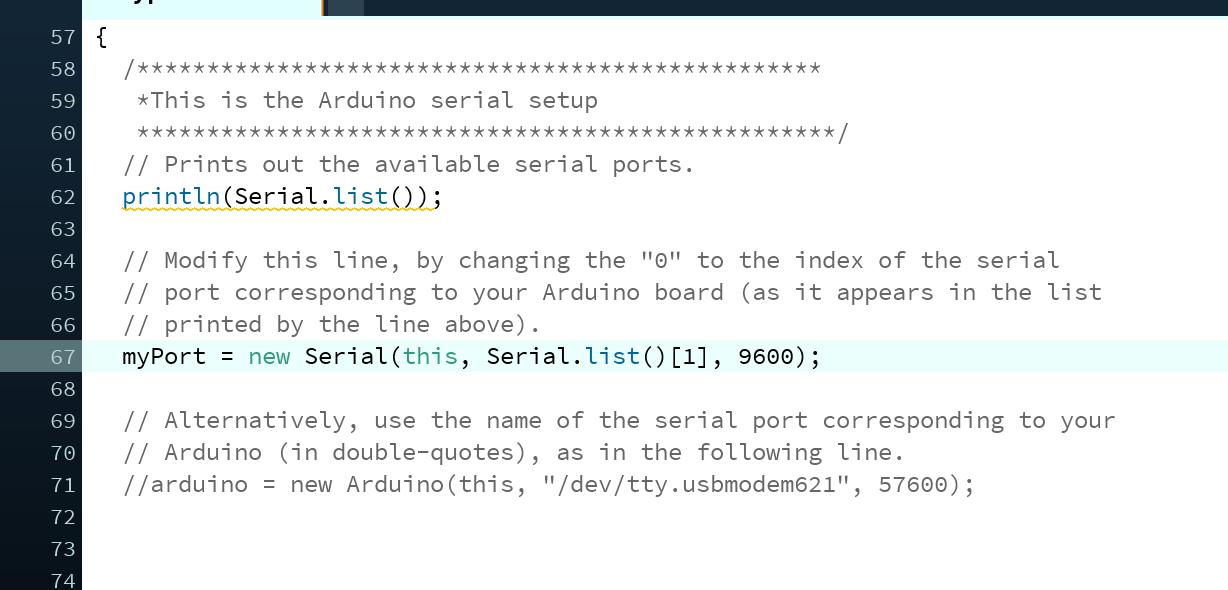

3. Change the port that the microcontroller is connected to in the code. Note that the ports are enumerated starting at the index of 0. An example would be, ” /dev/cu.Bluetooth-Incoming-Port /dev/tty.usbmodem621″ you would select port 1. Here is an example of the change of the port:

Port located at index 0

Port located at the index 1

4.Run the code again and wait for the IDE to say “GUI setup complete” and a single “r”. The “r” is very important because that means that the microcontroller is communicating with the application and is ready to receive a command from the application; the are stands for ready. After this step, the HyperRail is ready to go. Now we need to setup the hyperspectral camera.

5.Insert the camera in the case and then bolt in from behind or put a strap on the front. The bolts or strap are there for extra safety, not really neccesary, but it is still good to have.

6. Hook up the battery and turn on the camera.

7. Attach ethernet cable and start the data collection.

8. Detach the ethernet cable.

9. Star the HyperRail and wait for it to travel the rail.

DEMO VIDEO:

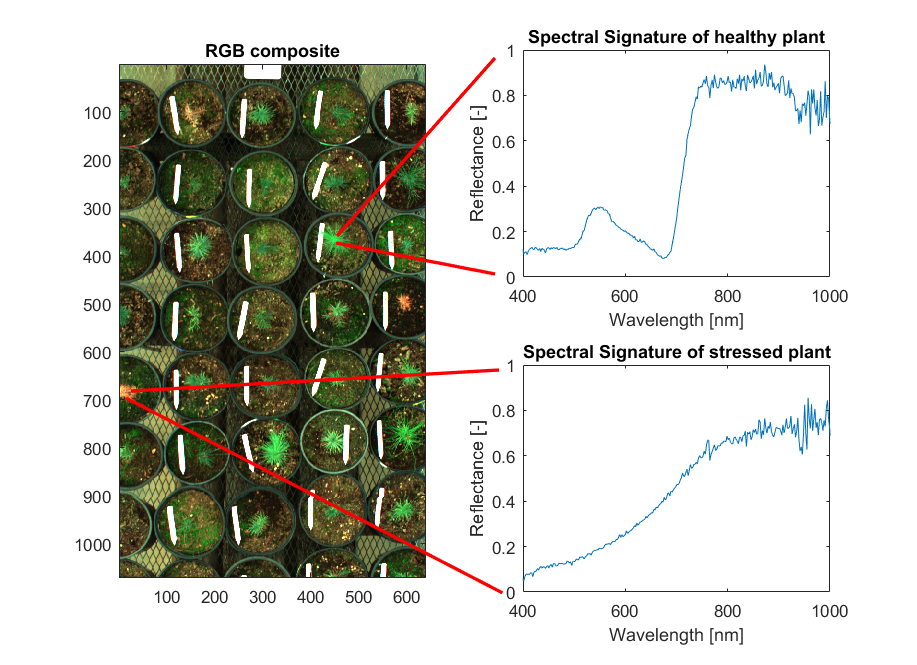

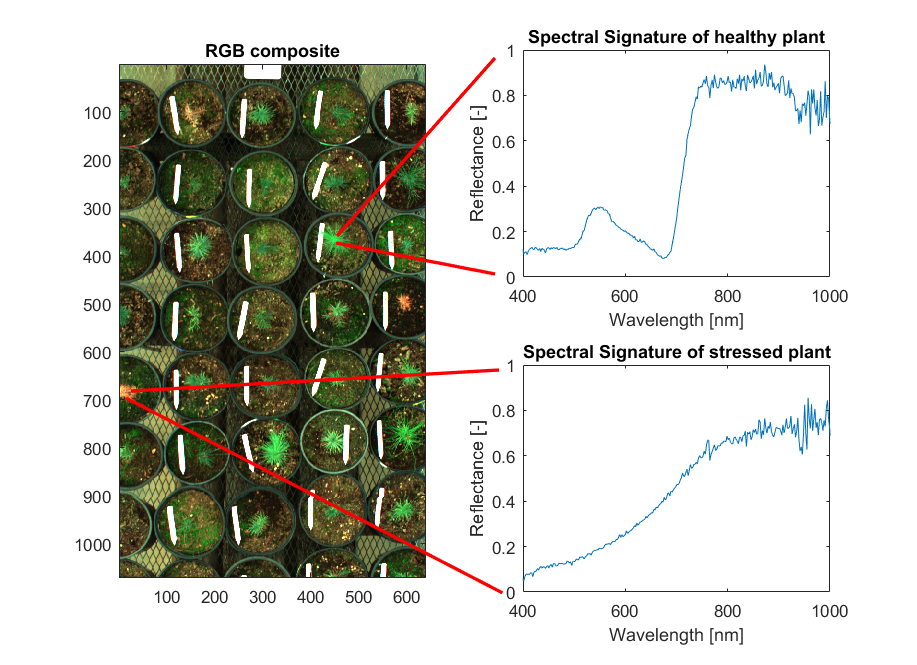

Here is an example fo the data collected from the hyperspectral camera:

Conclusions:

The HyperRail is working well. We will now move to improving the GUI for more functionality and upgrade the electronics for autonomous operation. This means that the sensor will in charge of moving the HyperRail’s carriage to where the sensor needs to be. We will be implementing the Feather microcontroller from Adafruit to do this because it has a LoRa radio to be able to communicate easily between feathers. I also need to run validation tests for the performance of the HyperRail to verify the precision of the movement of the carriage.