Abstract:

Much has happened with the samplers in the past two weeks! There are two categories of updates: those relevant to the Zurich Sampler and those relevant to the new versions of samplers. In short, the frames have been assembled for the new samplers and the PCBs are being soldered up; the new pumps arrived; the final pieces of the Zurich Sampler are coming together and it will be ready to ship very soon.

Updates:

New Sampler Updates:

Frame:

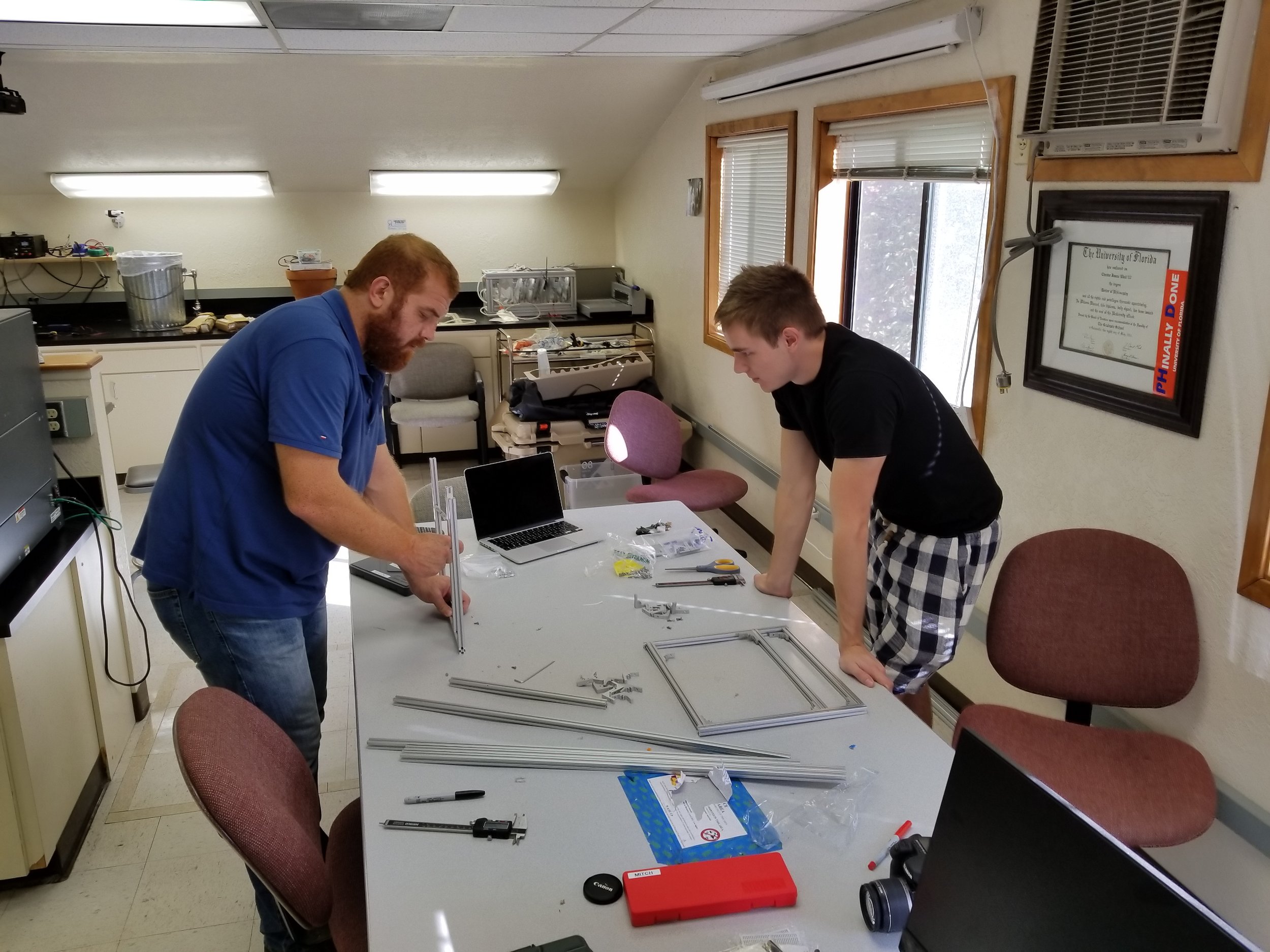

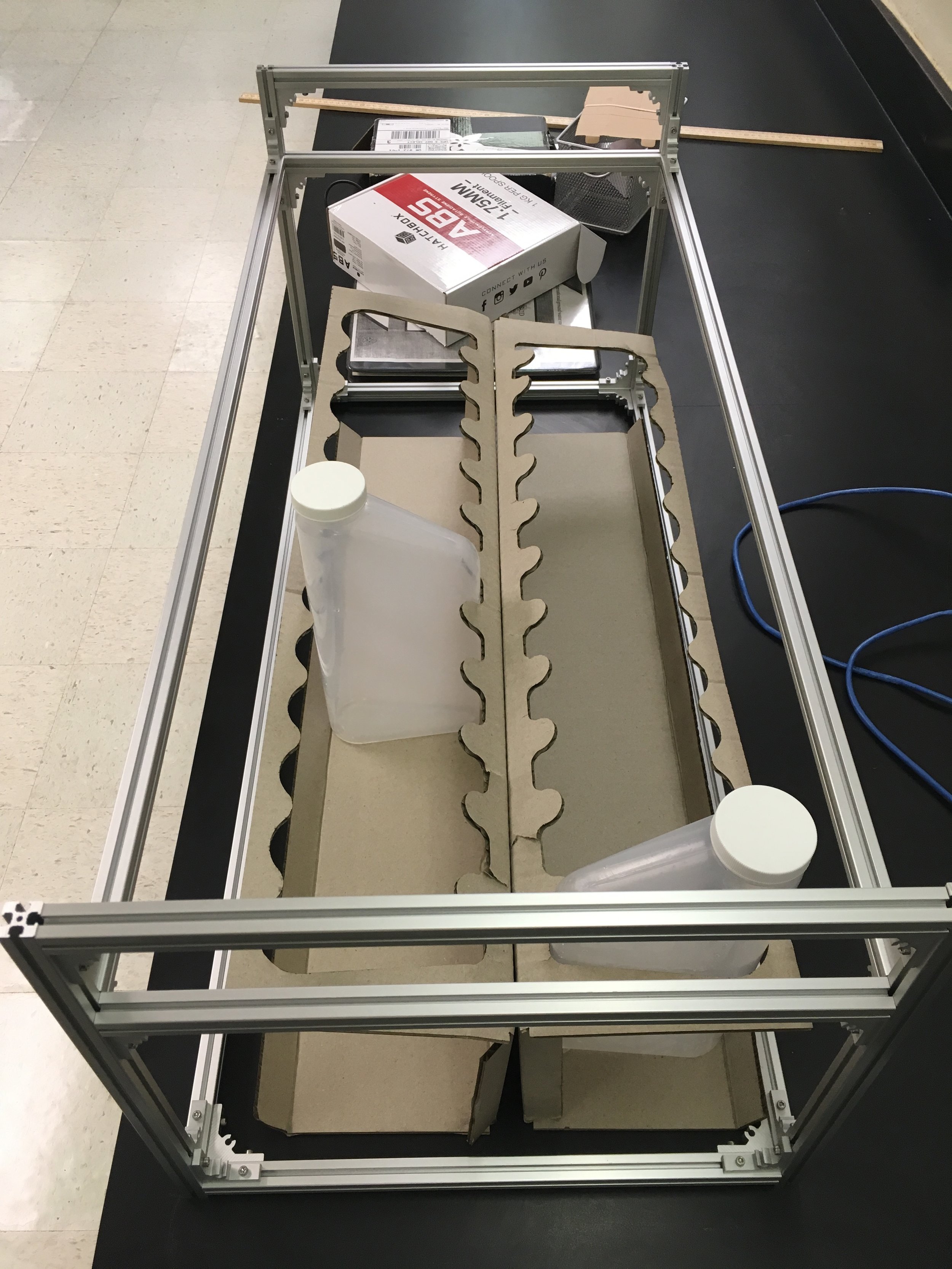

The sample-bag OPEnSampler frame was assembled by Adnan and I the other week and it fits snug in the Pelican 80QT rolling cooler. It fills up quite a bit of the space as intended, and there is extra room on the sides (the thickness of the wheel wells) for ice packs. Before more are assembled I think I will reduce the width of the sampler by about 5mm to account for the wells being slightly convex.

PCBs:

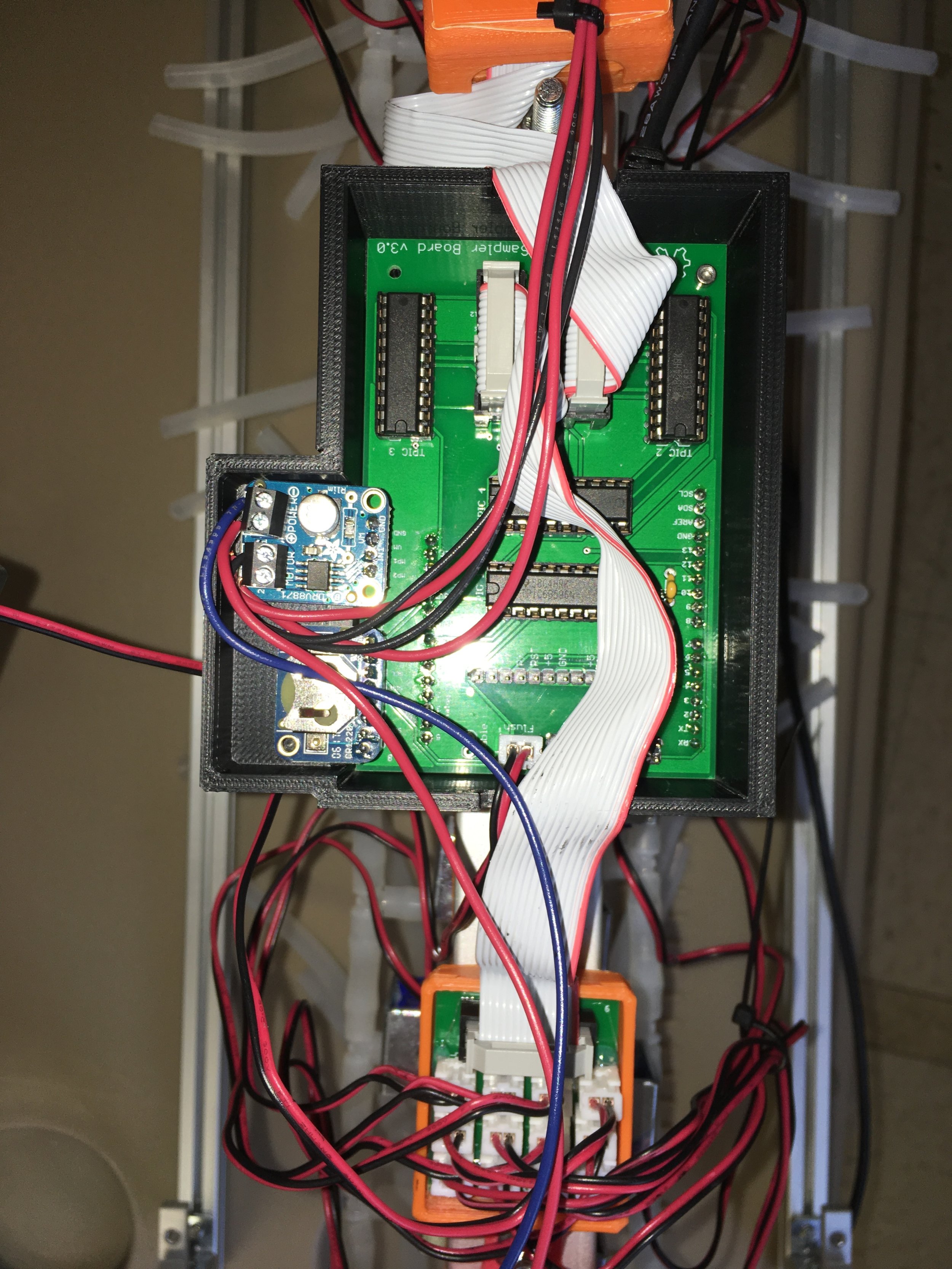

The Main Control Boards arrived the other week along with all the components of the two samplers. They look great! Azad and Adnan are soldering the components to them and will likely finish in a couple weeks.

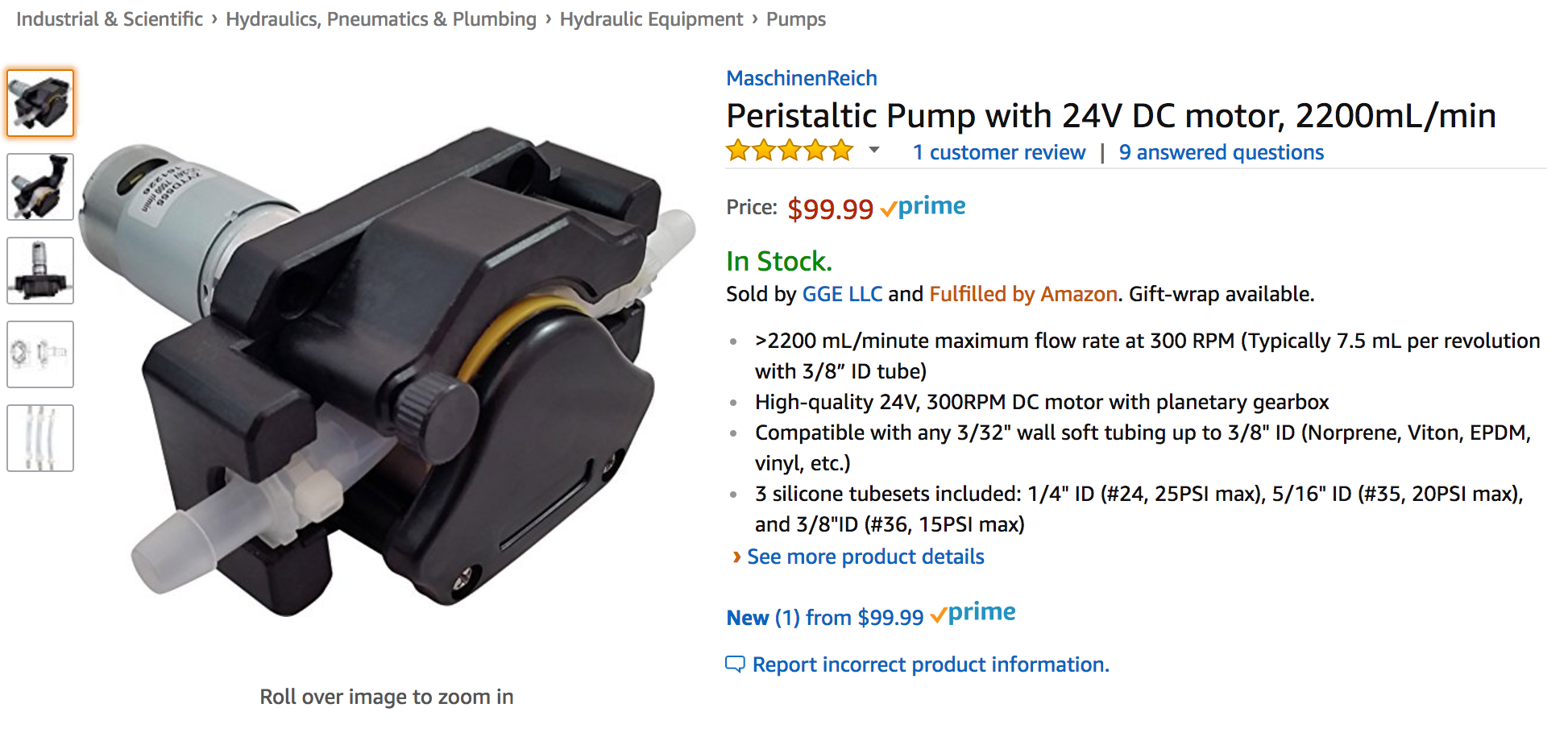

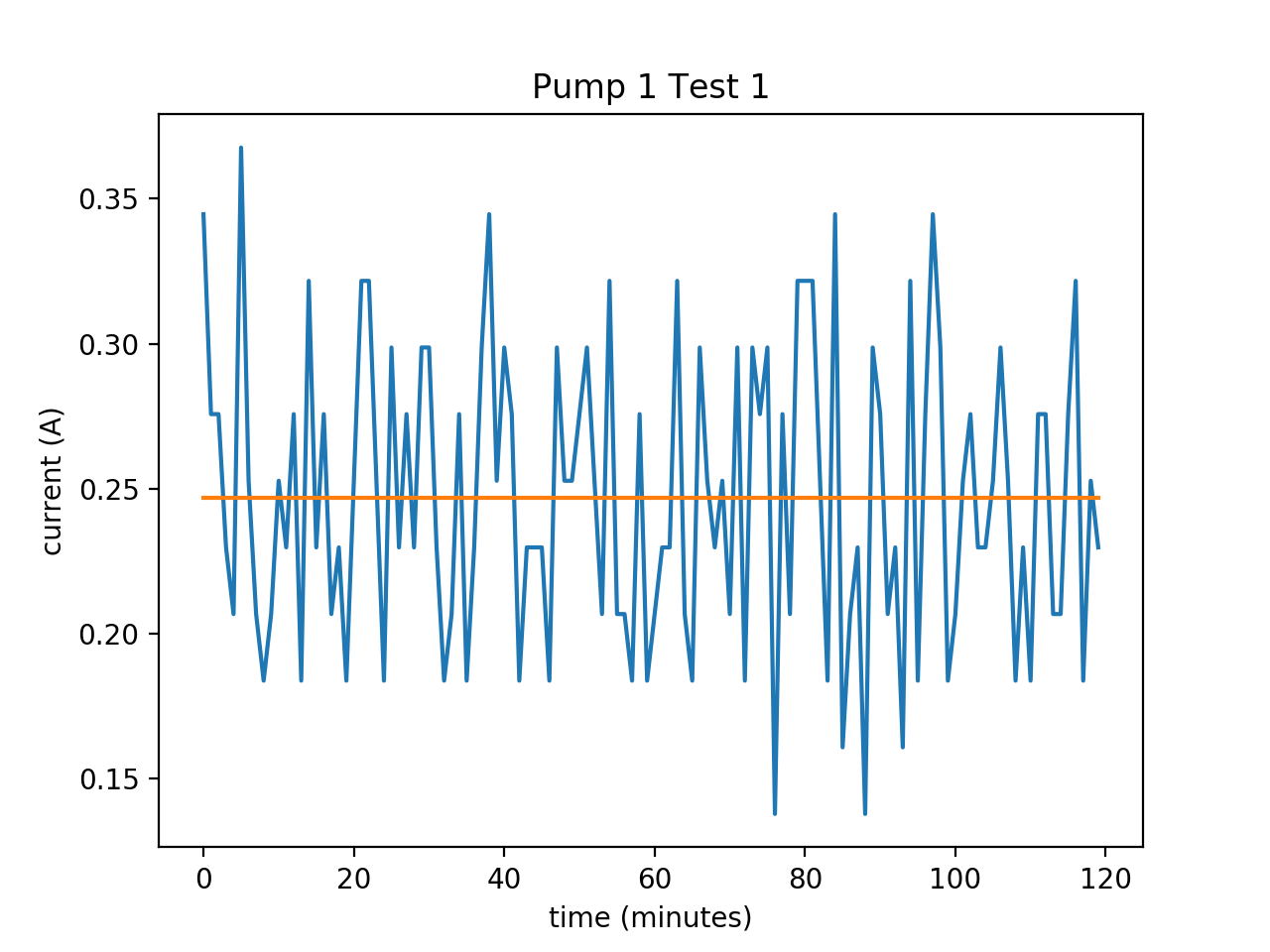

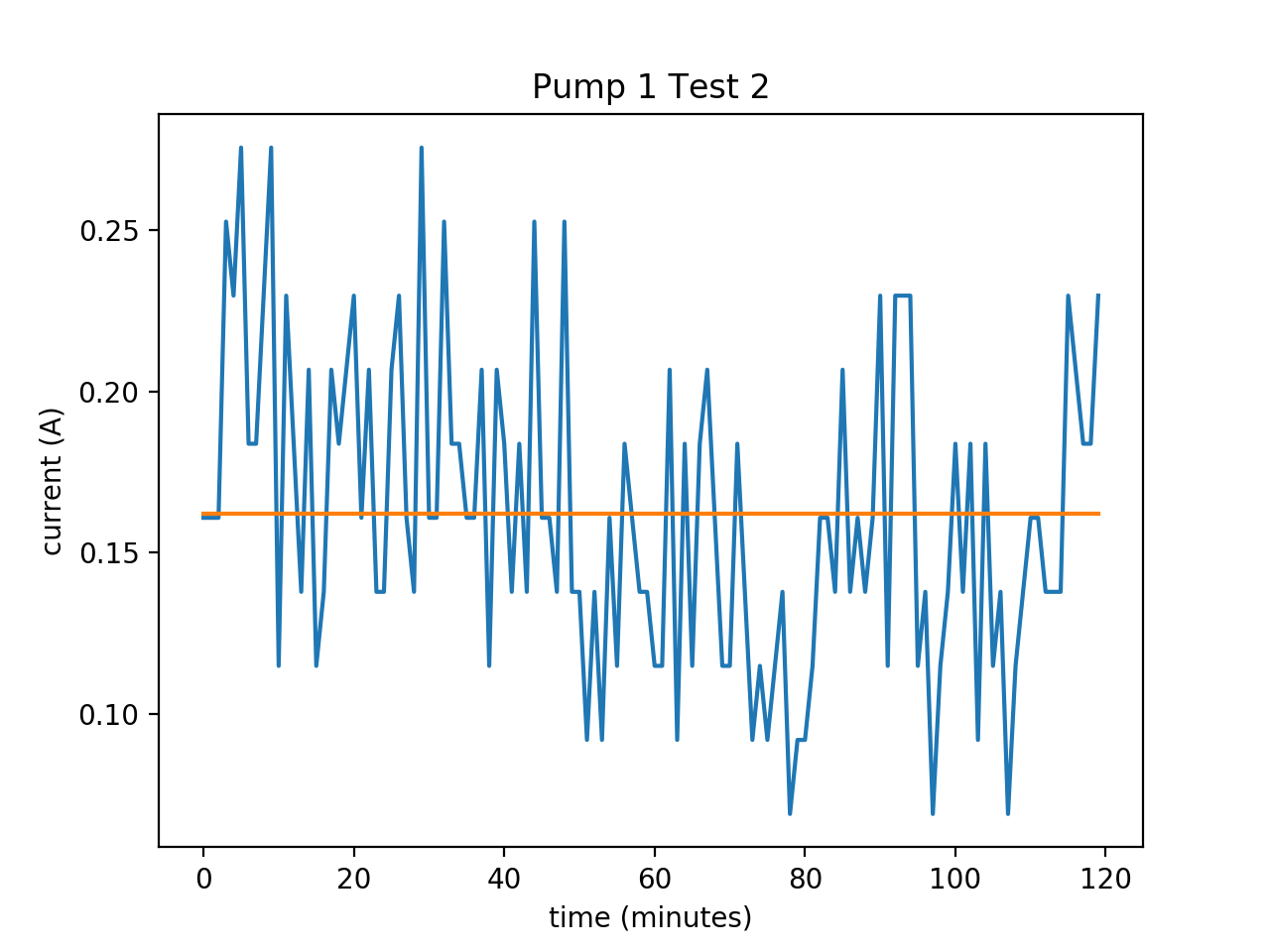

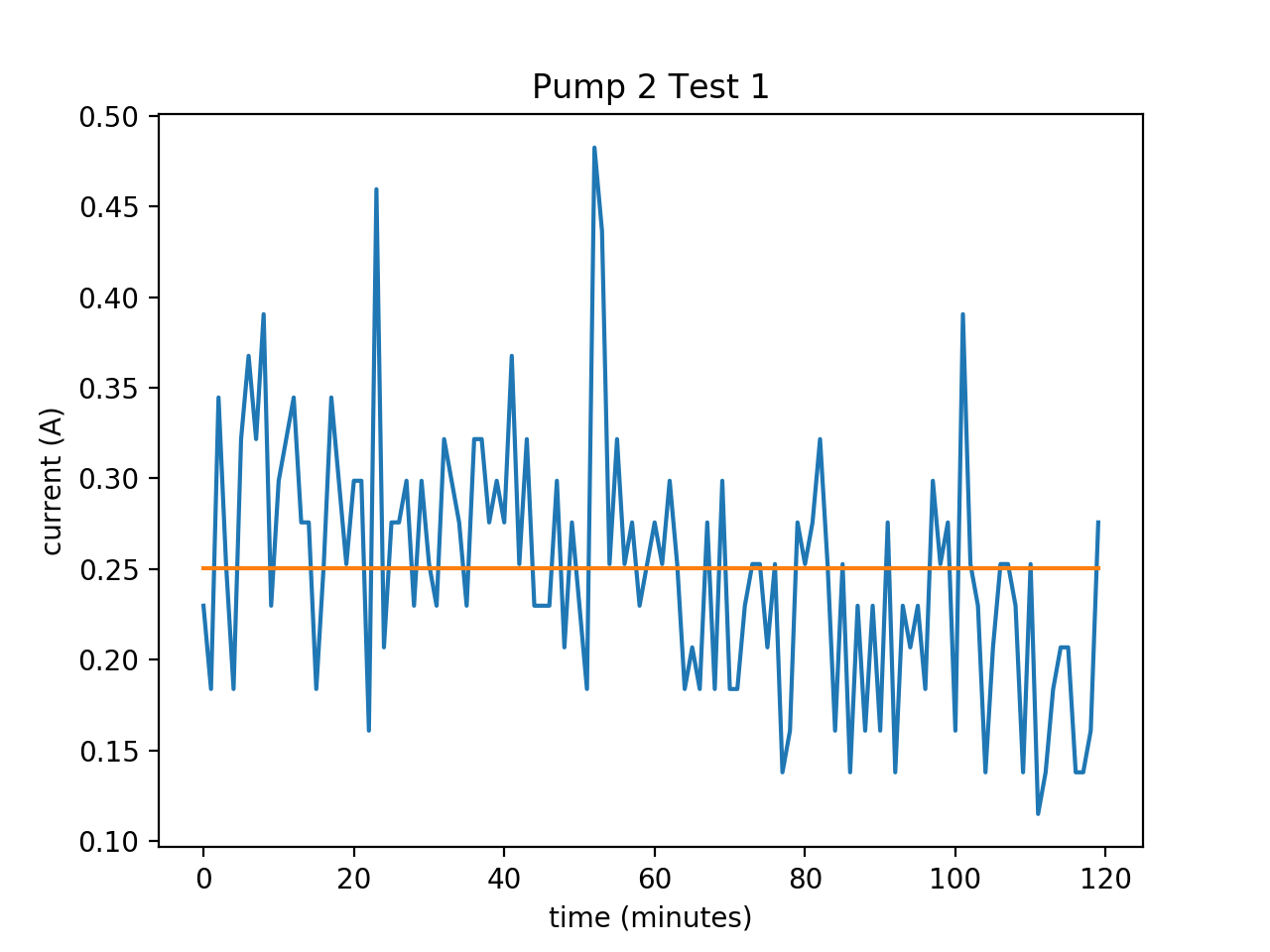

New Pumps:

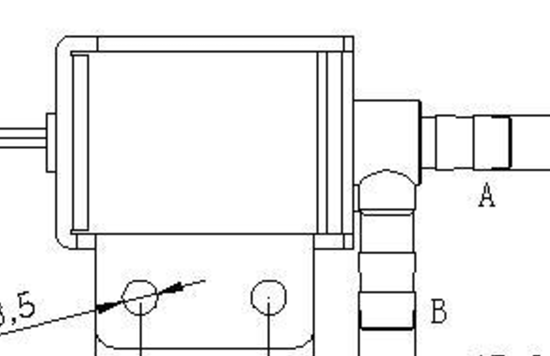

The new pumps arrived and we will be testing them soon. It looks proming but we will need to change either the tubing or the tube fittings to work with the rest of the sampler tubing. These will be added to the new samplers Azad and Adnan are assembling.

Android App:

In other news, three students will be working on adding an Android app to receive updates from and control the sampler remotely as their senior capstone project for their majors in computer science. In the coming weeks they will be contributing to the blog by introducing themselves and eventually posting updates on their work on the app.

Zurich Sampler Updates:

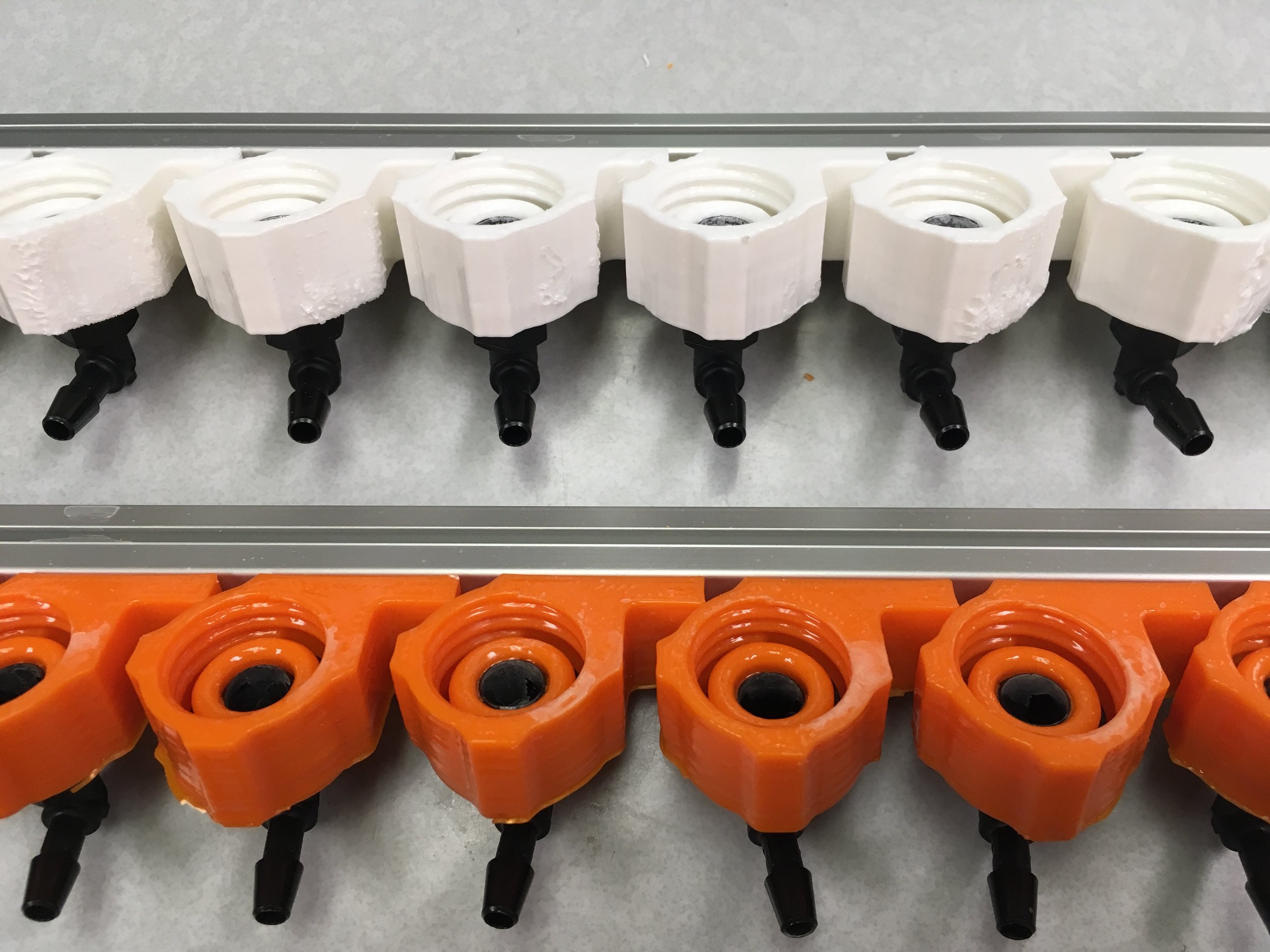

Quick Disconnect Fittings:

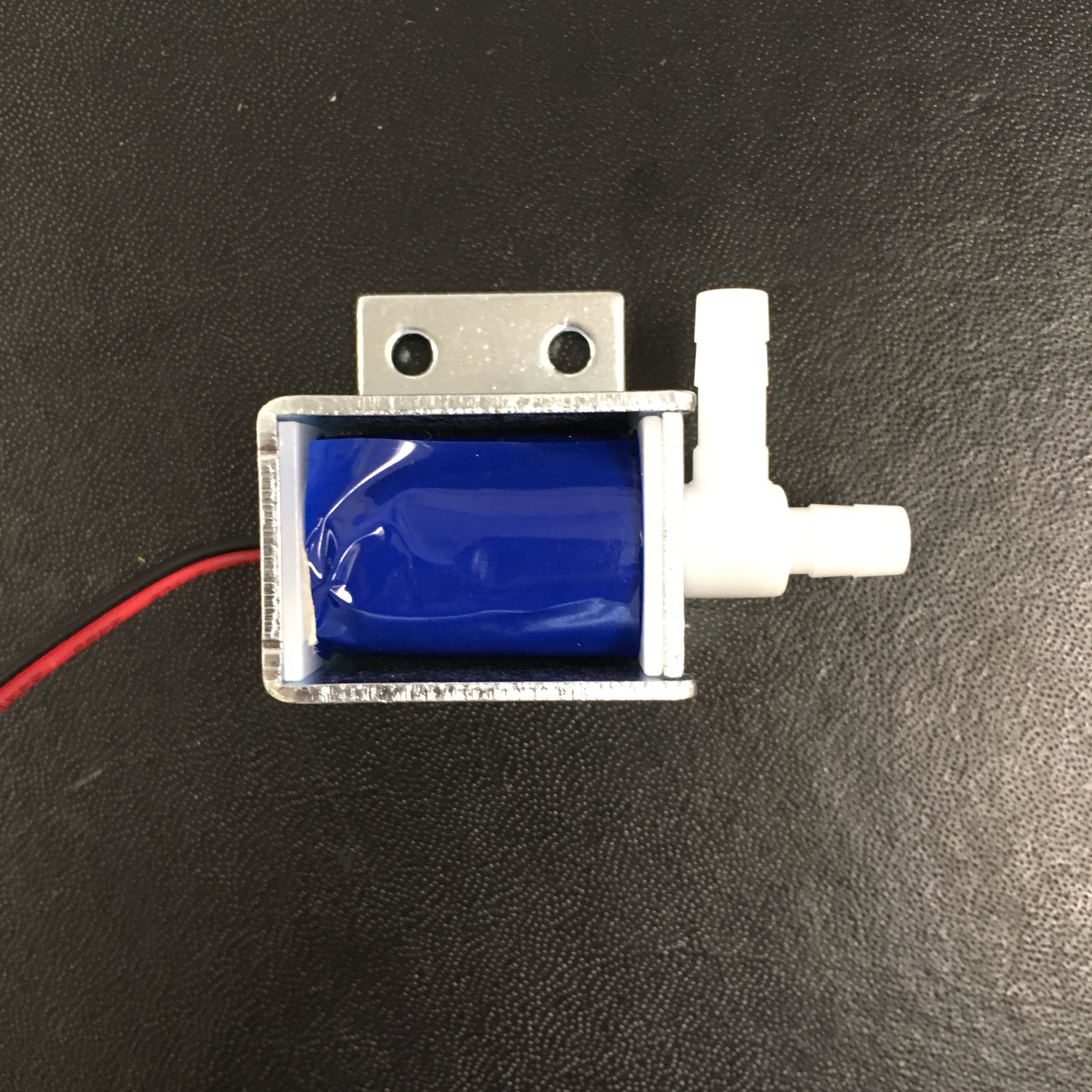

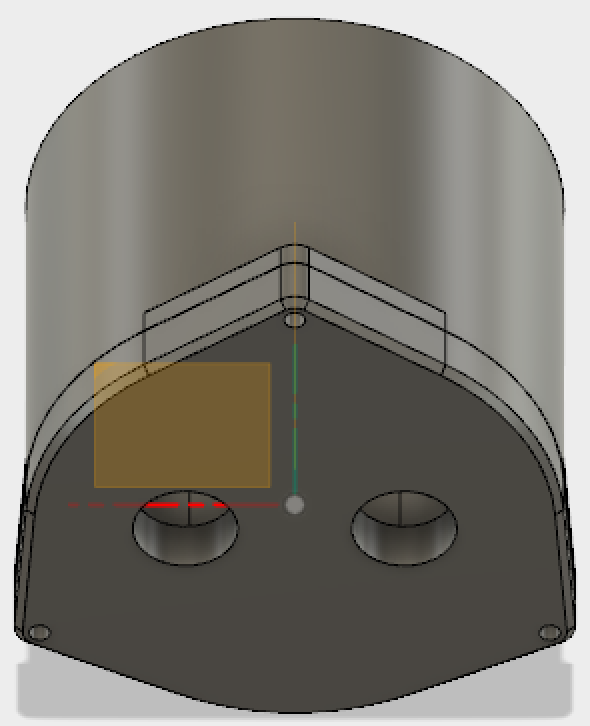

I finished the design of the endcap on which the two quick disconnect fittings are mounted and it is currently printing. Designing the endcap was more of a challenge than I initially predicted due to the awkward nature of the barbed fittings and the Pelican’s small outlet port. Because the threaded outlet on the Pelican cooler is too small to fit two fittings side-by-side, the endcap was designed in two pieces that would clamp together with an o-ring and three M2 screws. The male fittings can be threaded through the front panel with an o-ring to mitigate airflow. The sampler tubing can be pushed through the main body of the endcap while it is disconnected from the front panel, and then attached to the barbed ends of the fittings. The main body is then screwed onto the Pelican’s outlet port and the front panel is attached to the main body via M3 screws and nuts, completing the assembly. Intake tubing is attached to the intake fitting via the female quick disconnect fitting.

Filter:

The optional filters were quite easy to integrate into the design. The filter mesh is 470 micron stainless steel from Grainger with open ends. The front of the intake is blocked with a simple 3D-printed plate and the other end is blocked with another plate with a compression fitting screwed into it. All components of this assembly are glued with “ABS paste”, a solution of dissolved ABS plastic filament in acetone. The paste acts to weld the plastic components together.

Operator Interface:

The new Operator Interface turned out quite well. It consists of a 12V barrel jack port for powering the device with either a battery or a voltage regulator, a power On/Off switch, an enable switch for changing sampler modes (field use vs lab testing), an interrupt override button for initiating sampling in the field and also for lab testing, and a USB type B socket for communicating to the Arduino with a laptop. The panel is 3D printed and slides into the 15mm extrusion.

Conclusion:

There’s a ton of development happening on the OPEnSampler and I’m excited to showcase the new design once the two new samplers are completely assembled. In the coming weeks we will ship out the OPEnSampler for the first time, I will update the gitHub page with the latest designs and bill of materials, the capstone students will introduce themselves on this blog, the new pump will be tested, and the new samplers will be fully assembled.