Author: Brett Stoddard

Hi everyone, it’s been a while since the last update with the moisture sensor and a lot of progress has been made in that time. Progress has been made with confirming moisture readings and on the code side of things.

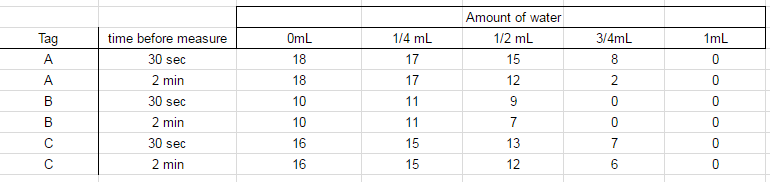

After a few more rounds of testing I have confirmed that the tags, for sure, can be used to measure a range of moisture levels. The test involved dropping different volumes of water onto the edge of a tag’s tail. The tail would soak some of that water up and onto the moisture sensitive part of the tag. The tails were about an inch long and increments of 25mL of water was dripped onto them using a precision eyedropper. The data (TABLE 1) showed a definite positive correlation which is good news. I also did a few trials on really wet and really dry soil and the tags were able to tell the difference between a desert and a swamp, although a more accurate of testing tags in soil was needed–which is where the next development comes into play.

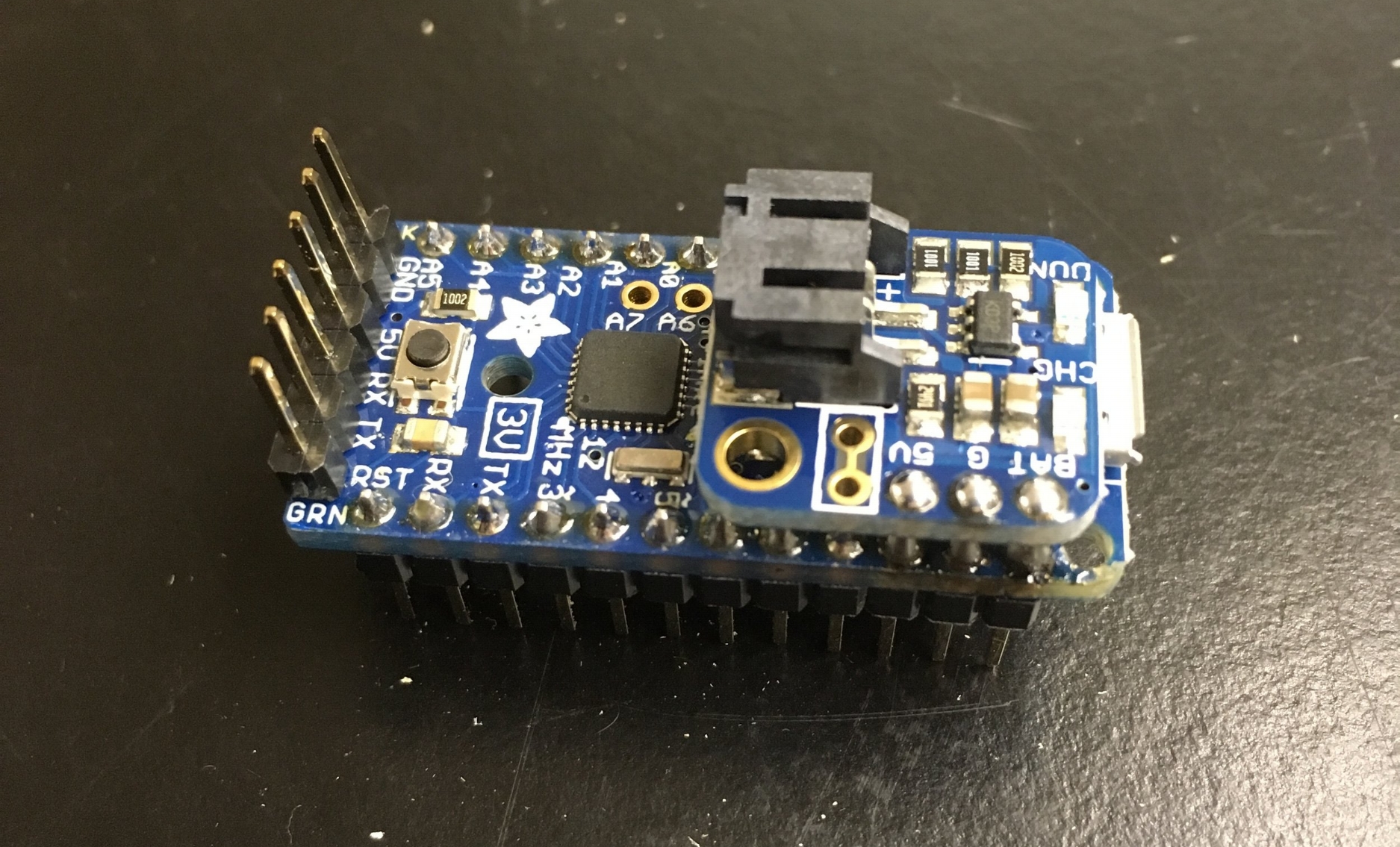

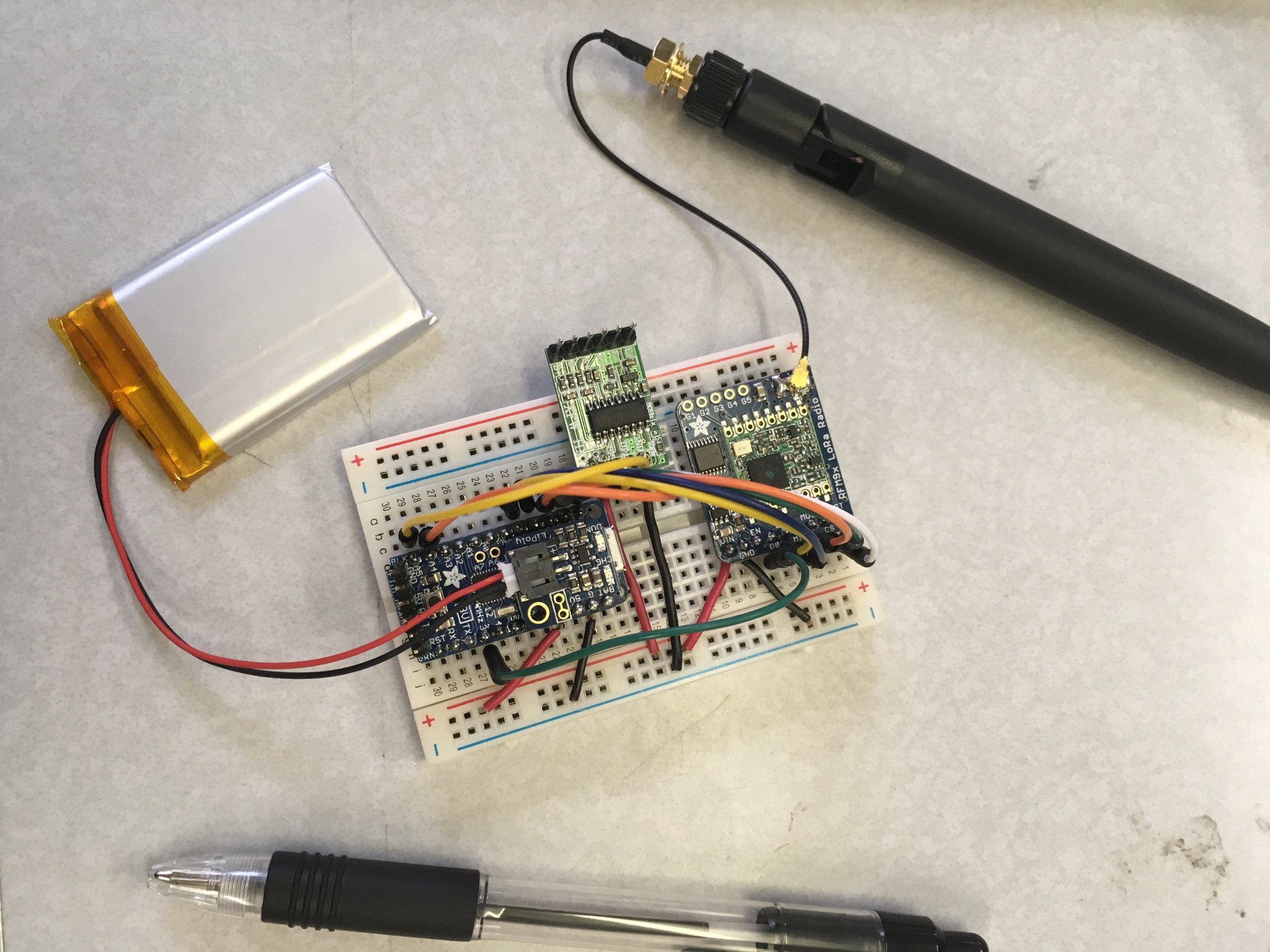

Since the last post, I have gotten the RFID reader shield and the GPS logger shield to work together. I have added a polished example code bit onto the GitHub library. Available here, it records the average value of the RFID tag after 100 measurements then records measurement from a YL-69+YL-38 moisture sensor. The plan with this reader is to eventually use it to calibrate the values that we’re currently receiving off of the RFID tags (0 for wet, 20 for dry). This will involve setting the YL probe and RFID tag onto the same soil sample and letting it sit there for a few days and take measurements periodically as the soil drys. After we get this data we will be able to tell how well the RFID tags will work for measuring soil moisture.

I have also gone through and updated a little bit of the other example codes to make them work better.

Cheers, Brett Stoddard